Overview

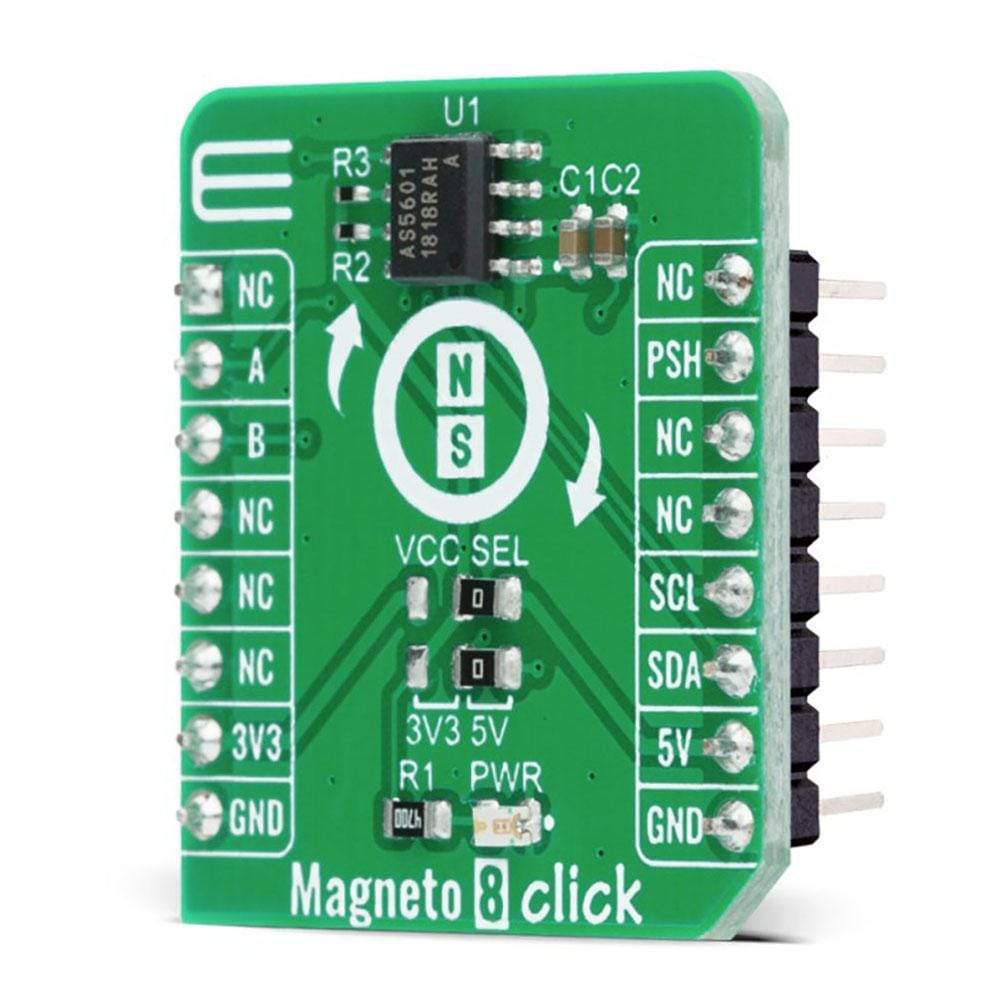

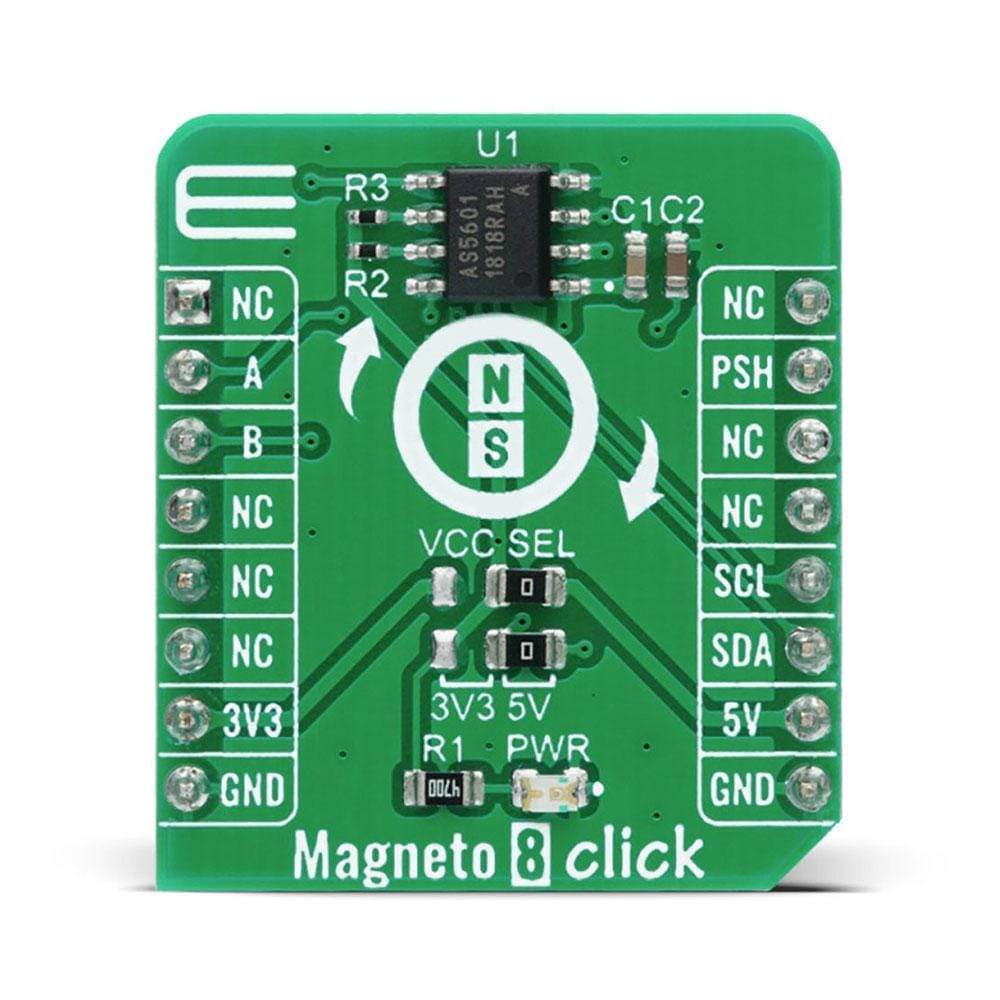

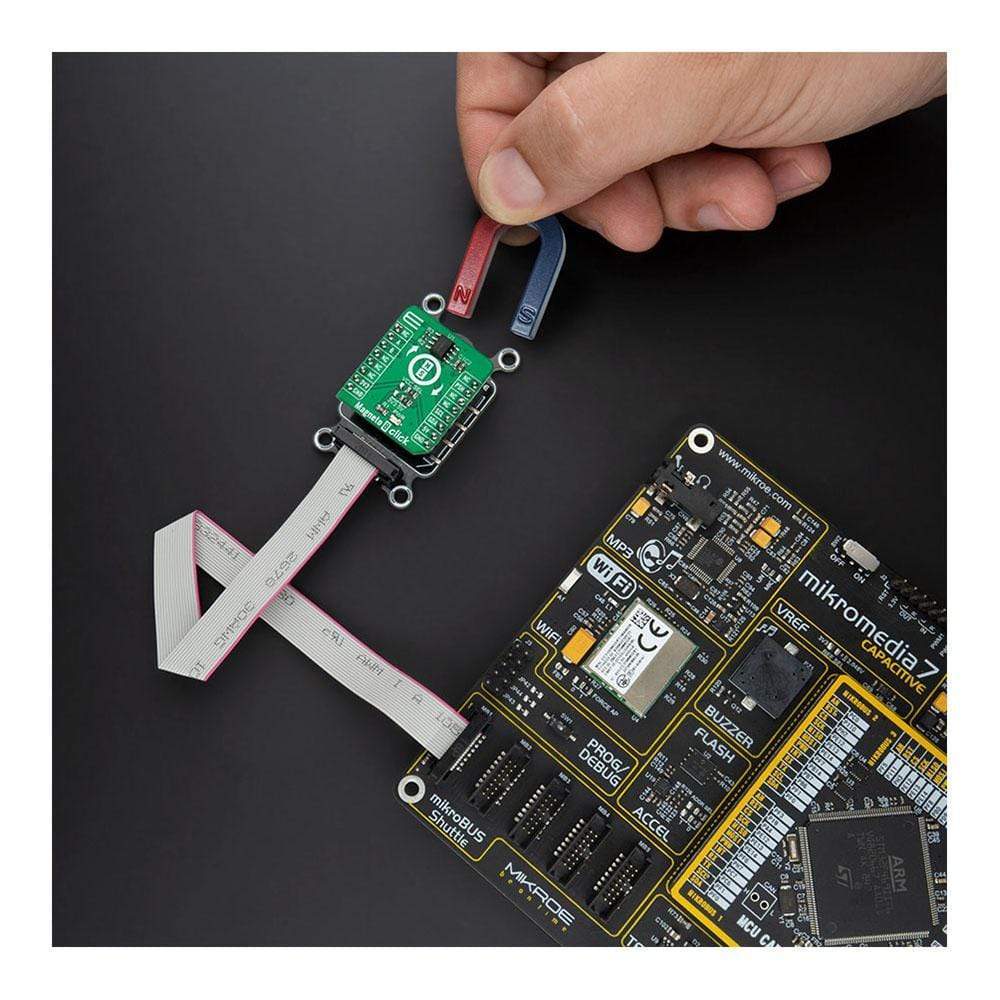

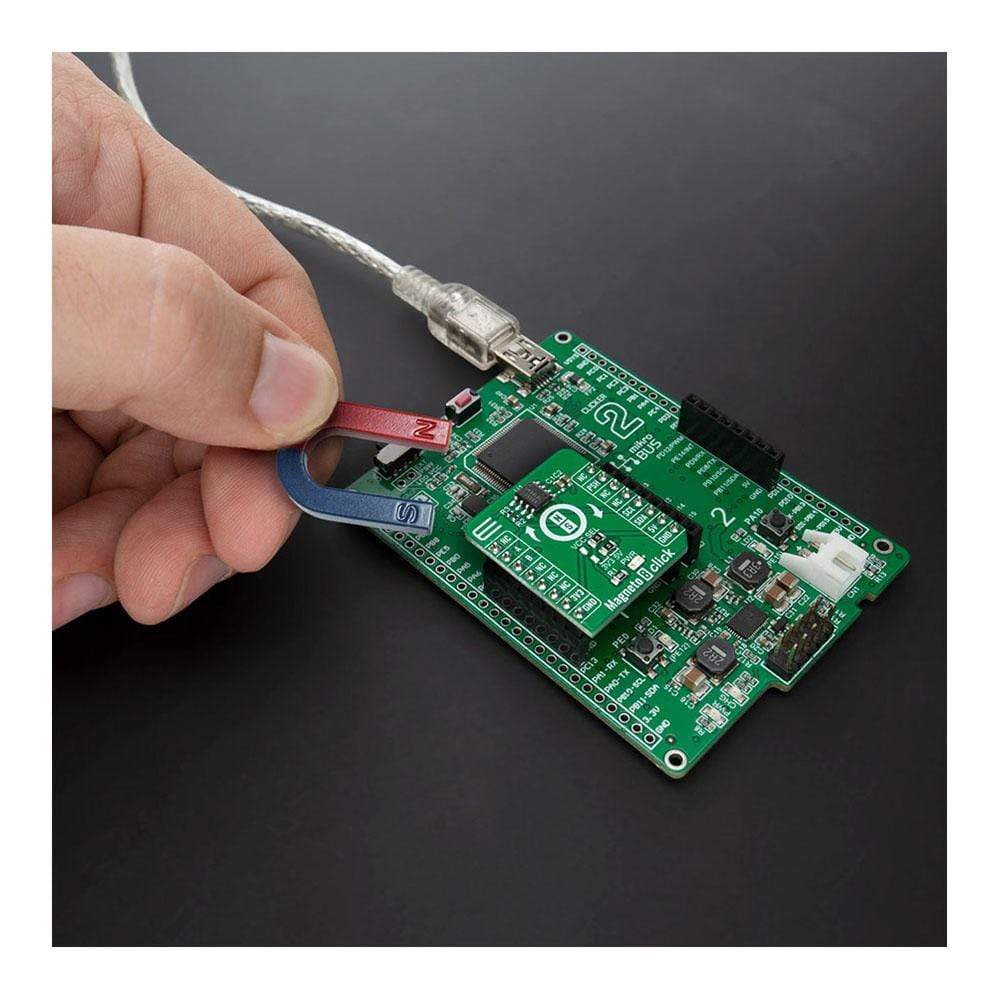

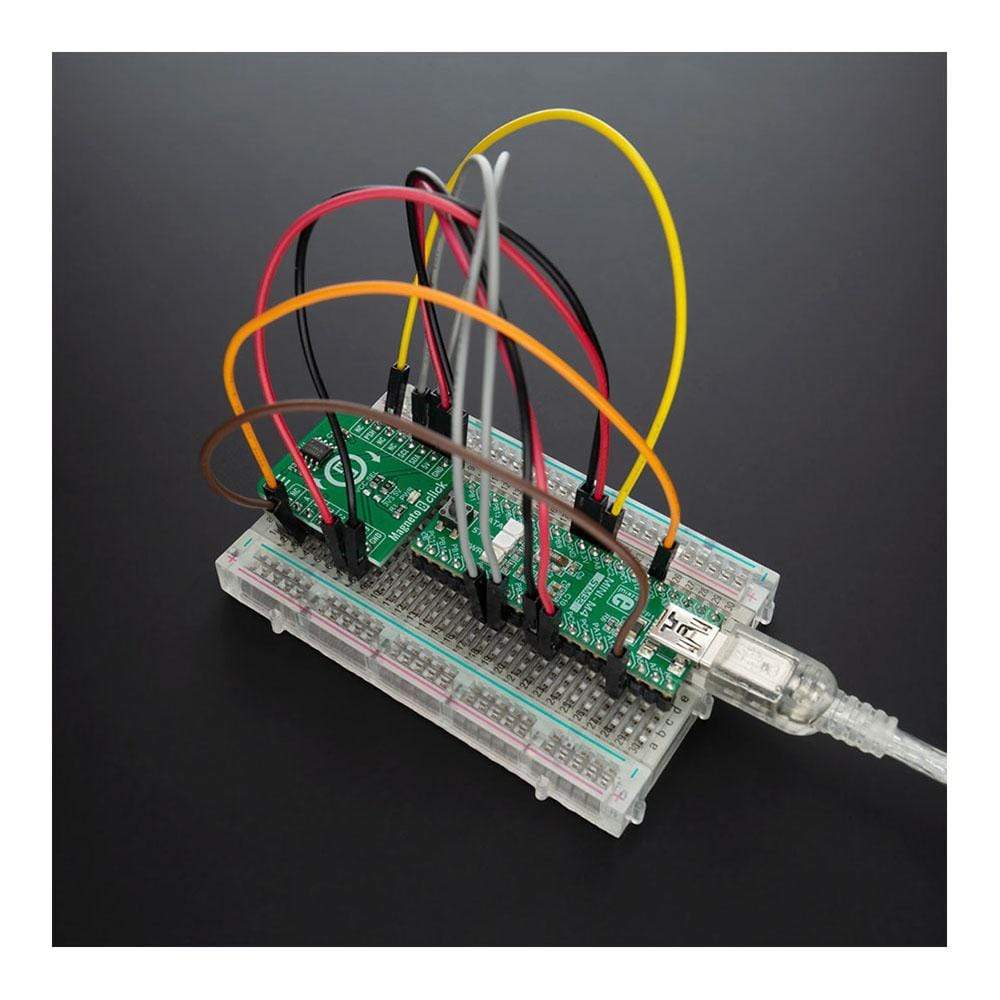

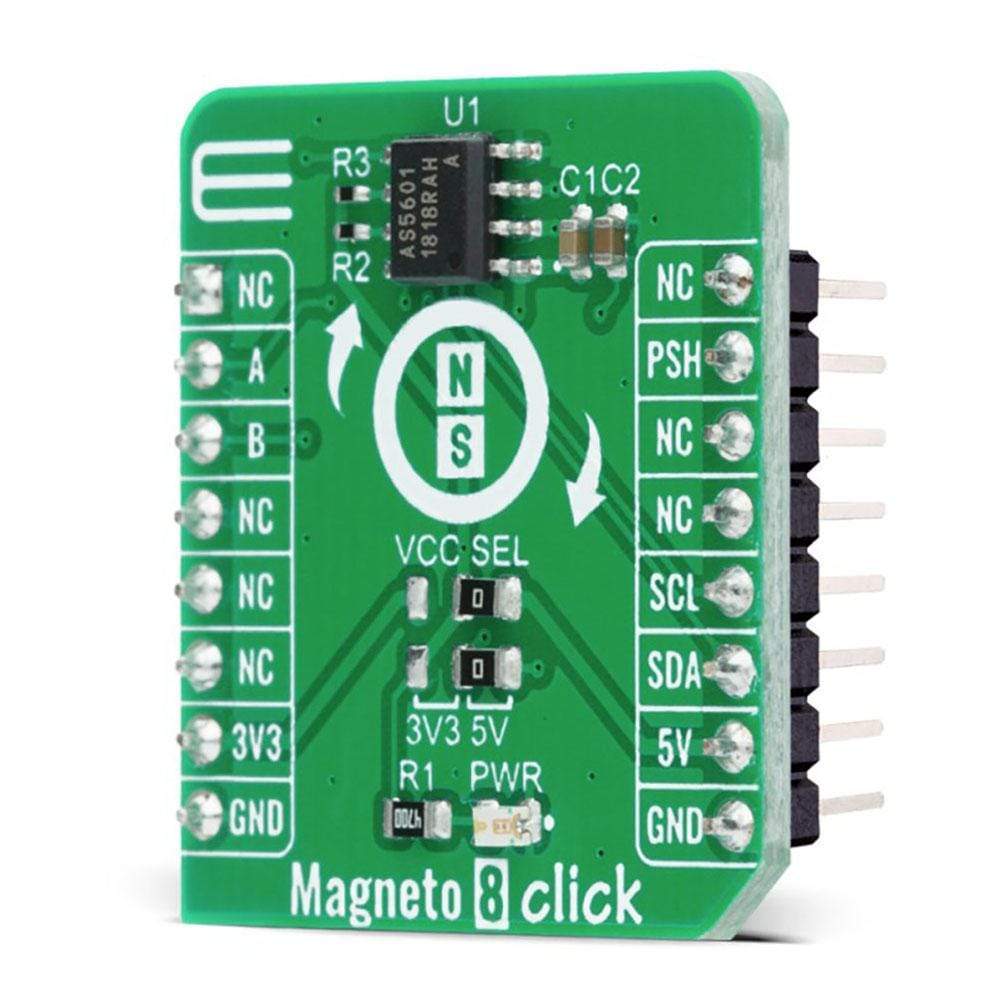

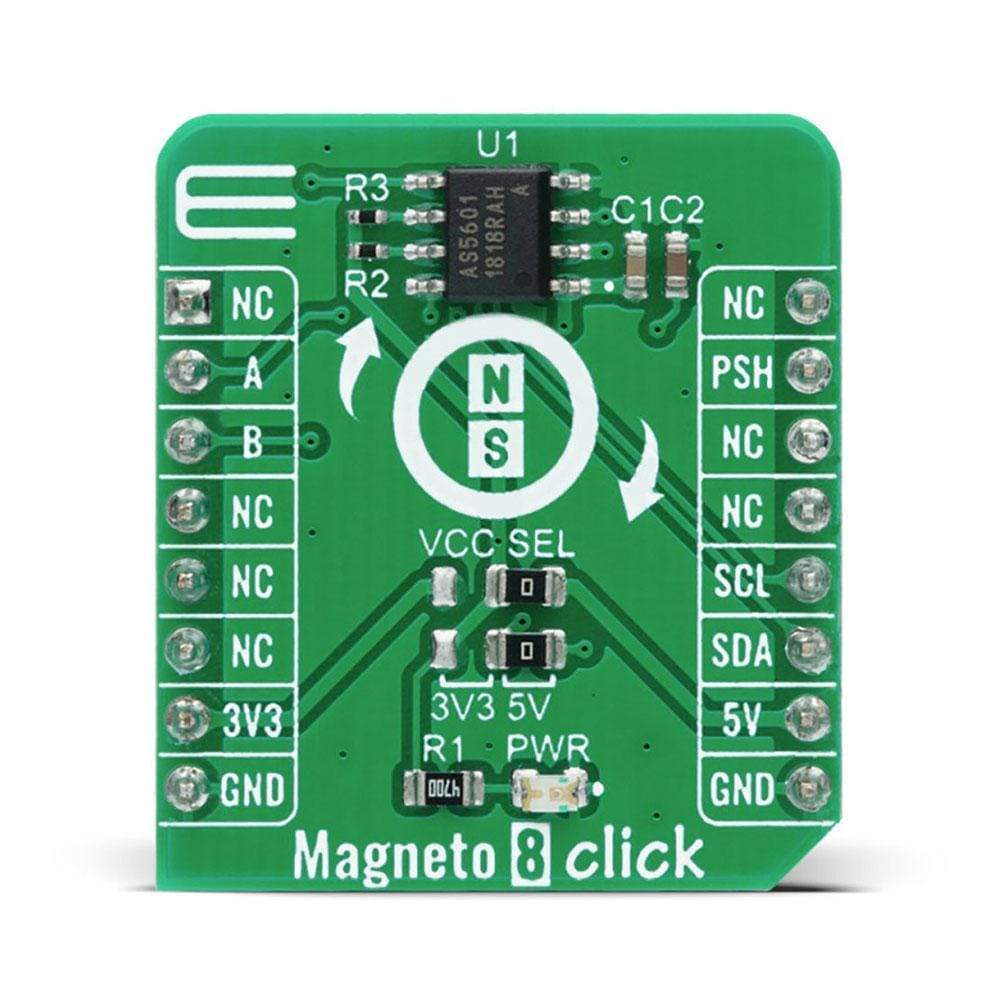

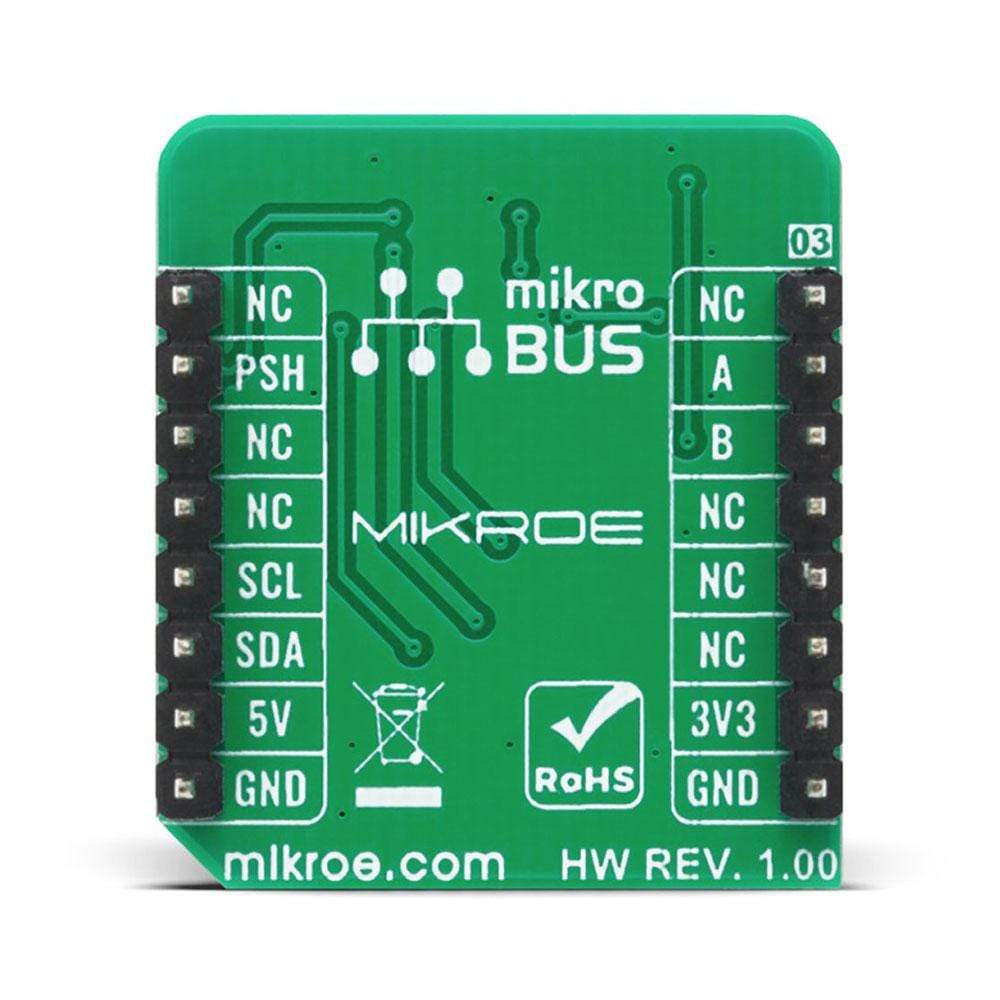

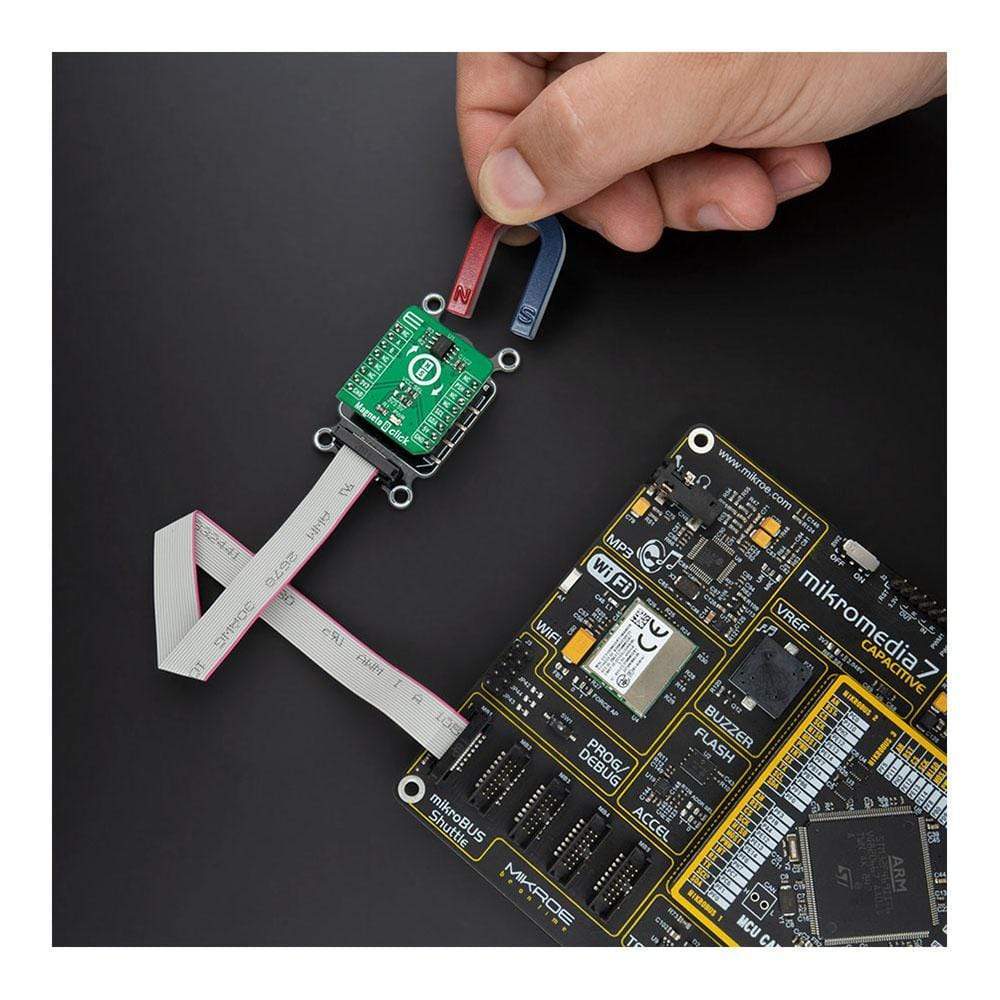

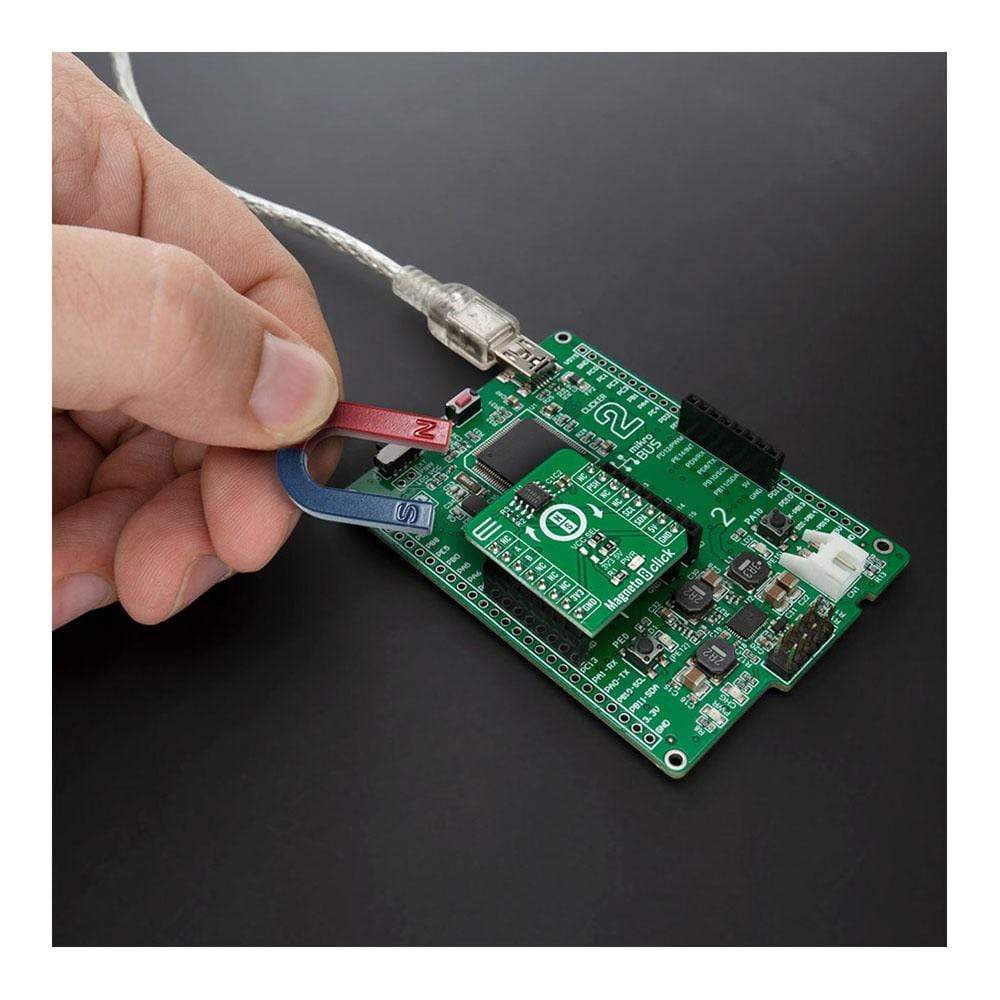

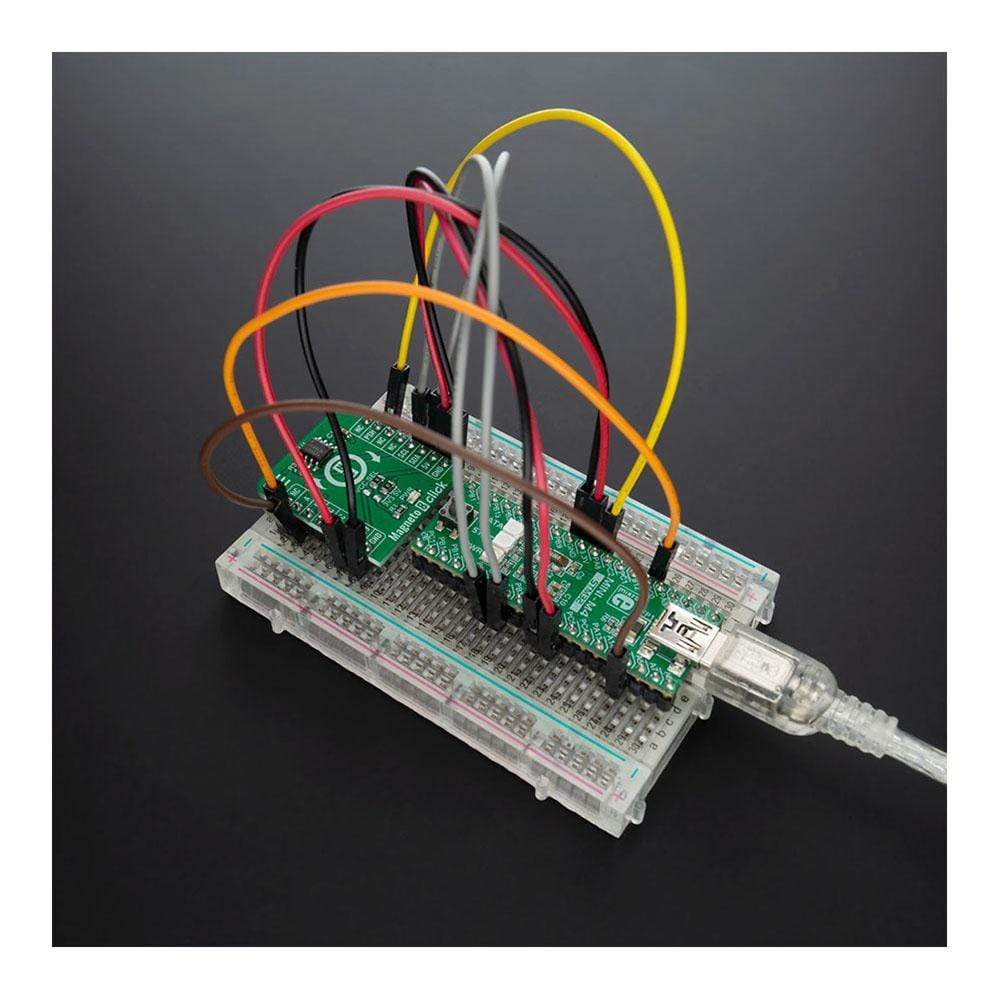

The Magneto 8 Click Board™ is a compact add-on board that contains an easy-to-program magnetic rotary position sensor with incremental quadrature (A/B) and 12-bit digital outputs. This board features the AS5601, 12-bit programmable contactless encoder IC from AMS-AG. This Click Board™ is based on a planar Hall sensor technology, supports an industry-standard I2C interface, and it measures the orthogonal component of the flux density (Bz) from an external magnet. It also provides a smart low-power mode that automatically reduces power consumption. Magneto 8 Click has many features that make it attractive for various applications such as angular position measurement solutions, encoder replacement, contactless magnetic position sensors, and more.

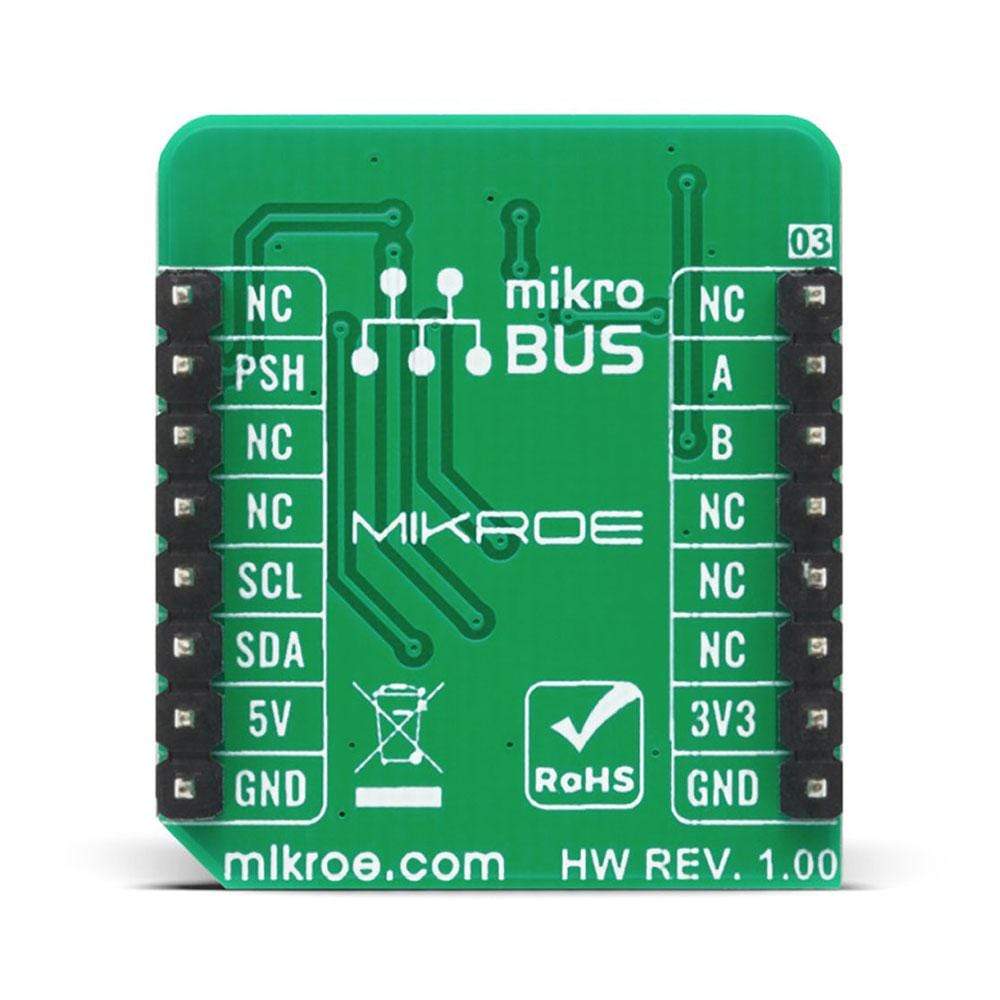

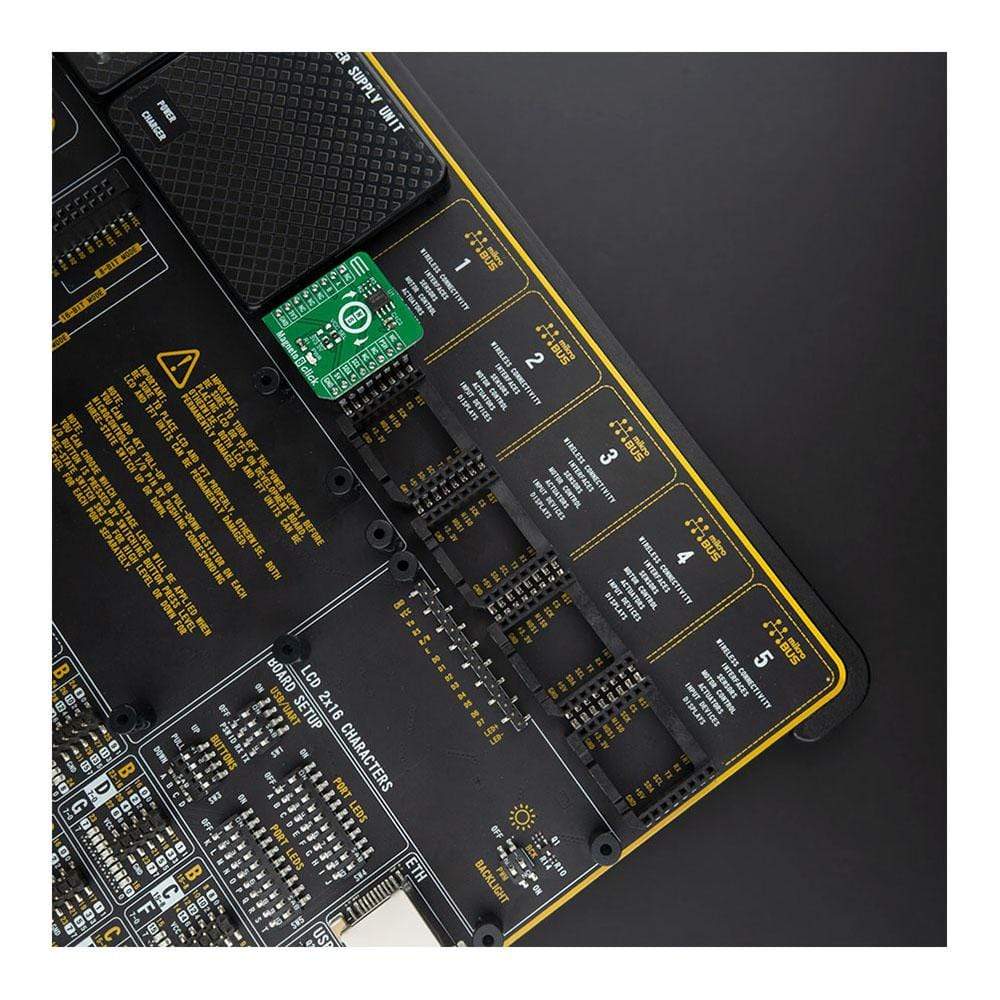

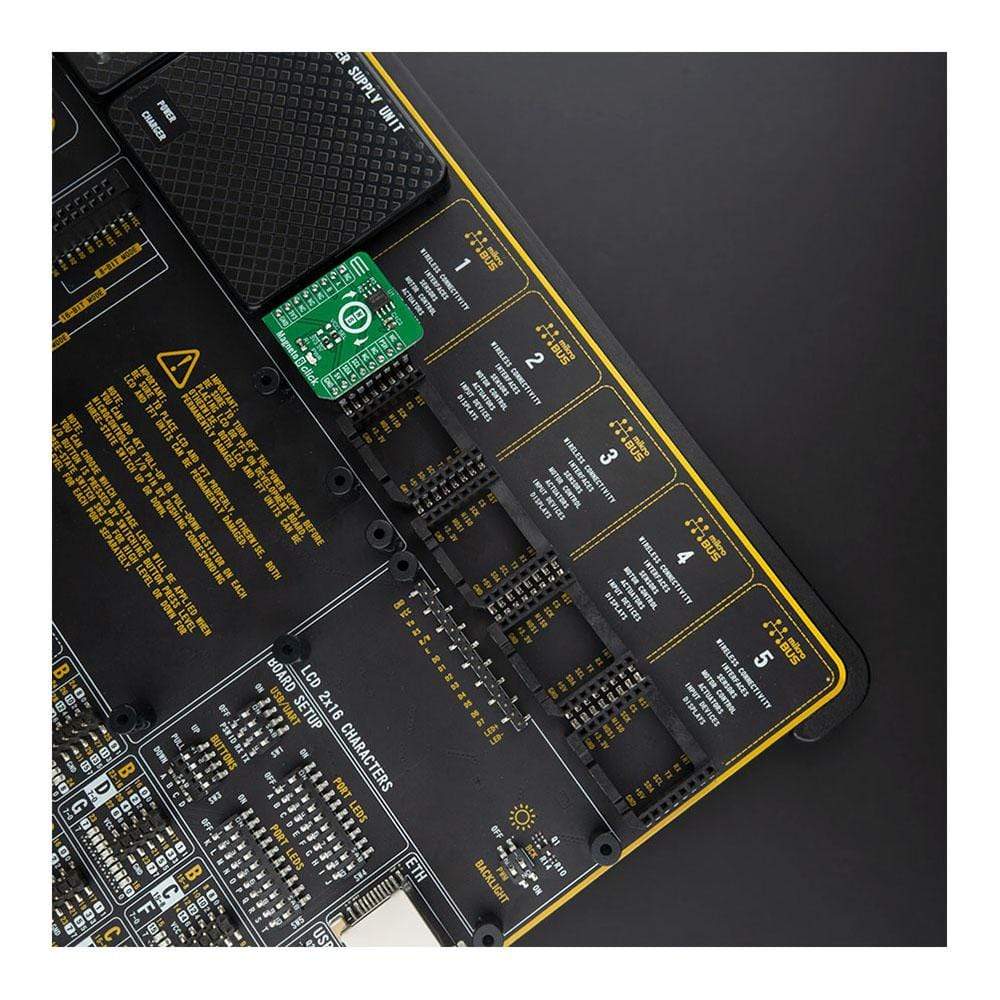

The Magneto 8 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Das Magneto 8 Click Board™ ist eine kompakte Zusatzplatine, die einen einfach zu programmierenden magnetischen Drehpositionssensor mit inkrementeller Quadratur (A/B) und 12-Bit-Digitalausgängen enthält. Diese Platine verfügt über den 12-Bit programmierbaren kontaktlosen Encoder-IC AS5601 von AMS-AG. Dieses Click Board™ basiert auf einer planaren Hall-Sensor-Technologie, unterstützt eine I2C-Schnittstelle nach Industriestandard und misst die orthogonale Komponente der Flussdichte (Bz) von einem externen Magneten. Es bietet außerdem einen intelligenten Energiesparmodus, der den Stromverbrauch automatisch reduziert. Magneto 8 Click verfügt über viele Funktionen, die es für verschiedene Anwendungen attraktiv machen, wie z. B. Lösungen zur Winkelpositionsmessung, Encoder-Ersatz, kontaktlose magnetische Positionssensoren und mehr.

Das Magneto 8 Click Board™ wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4204

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.017 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027380150

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.