Overview

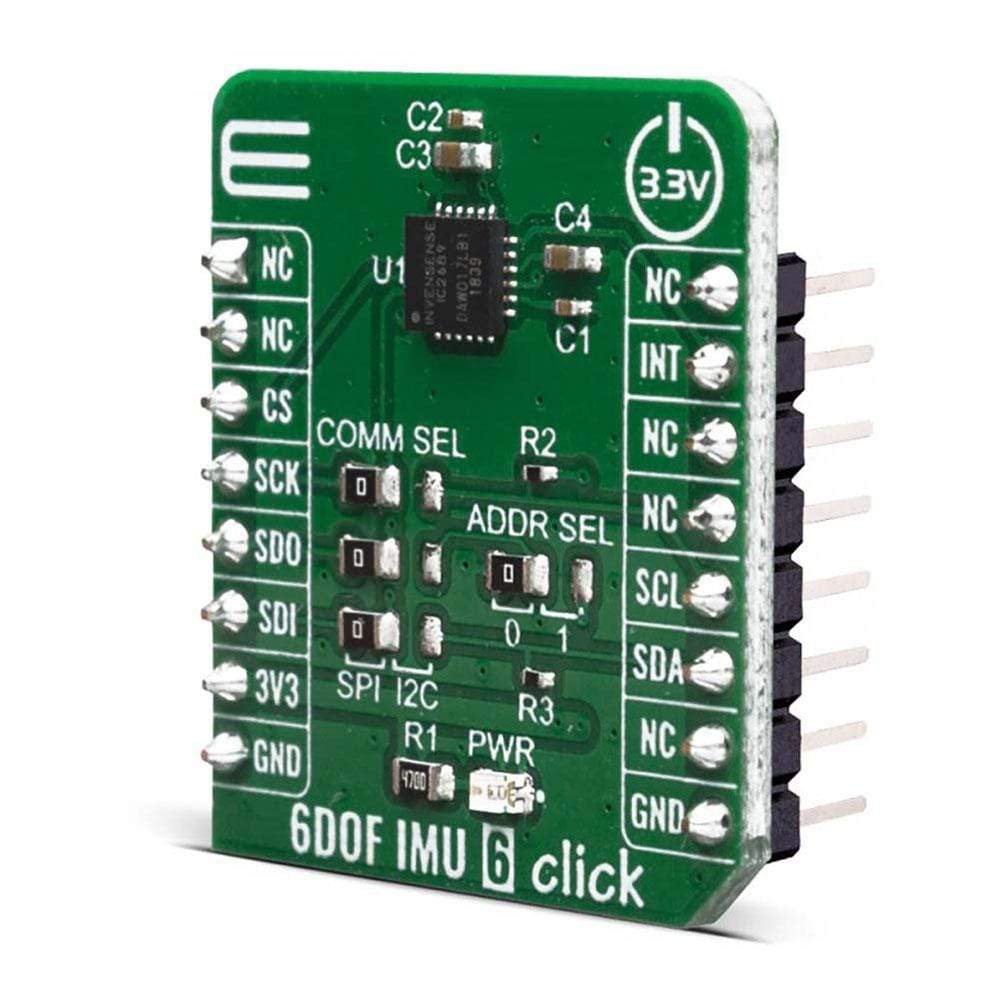

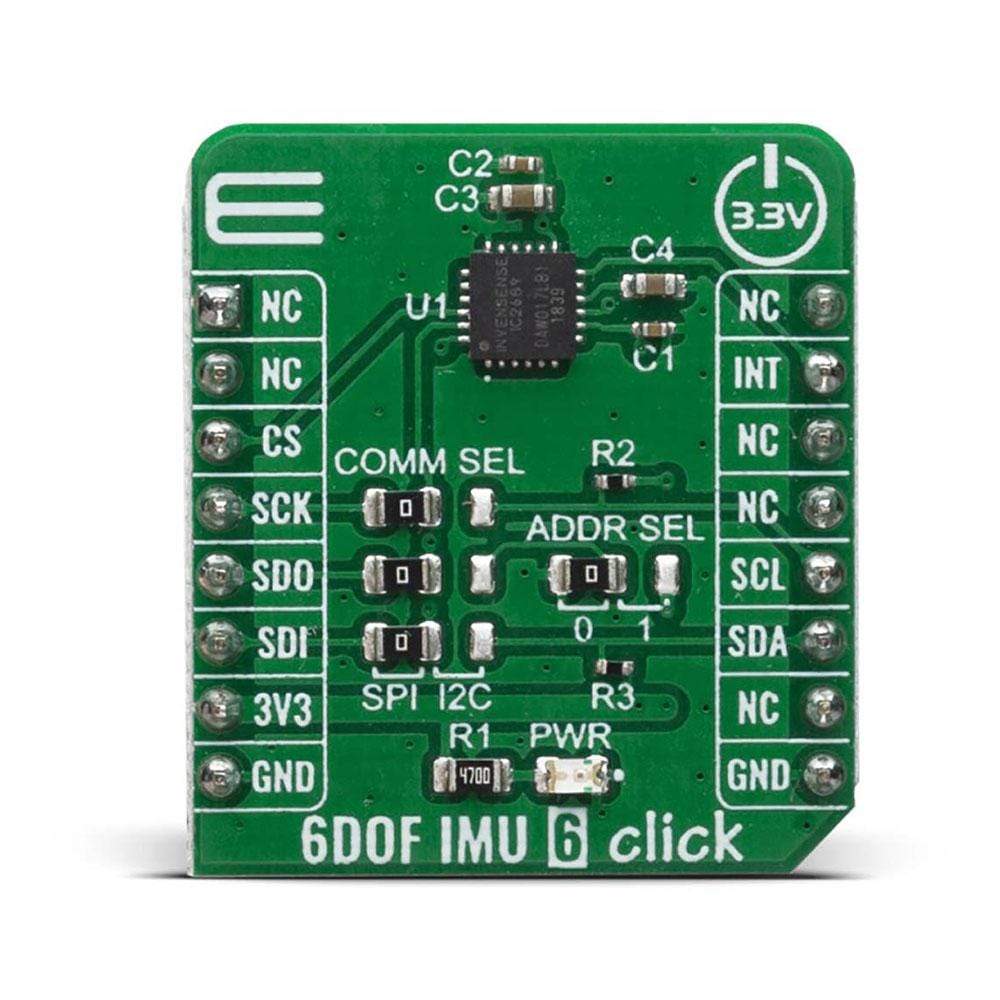

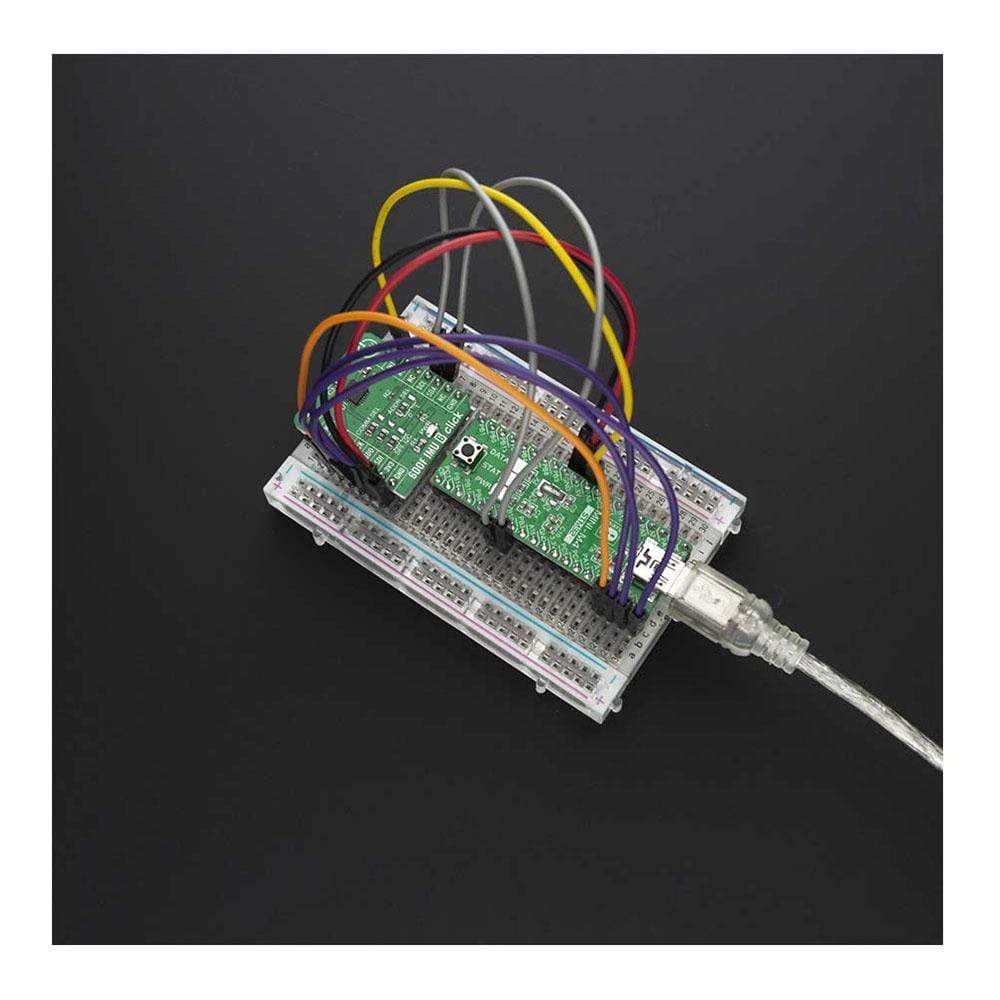

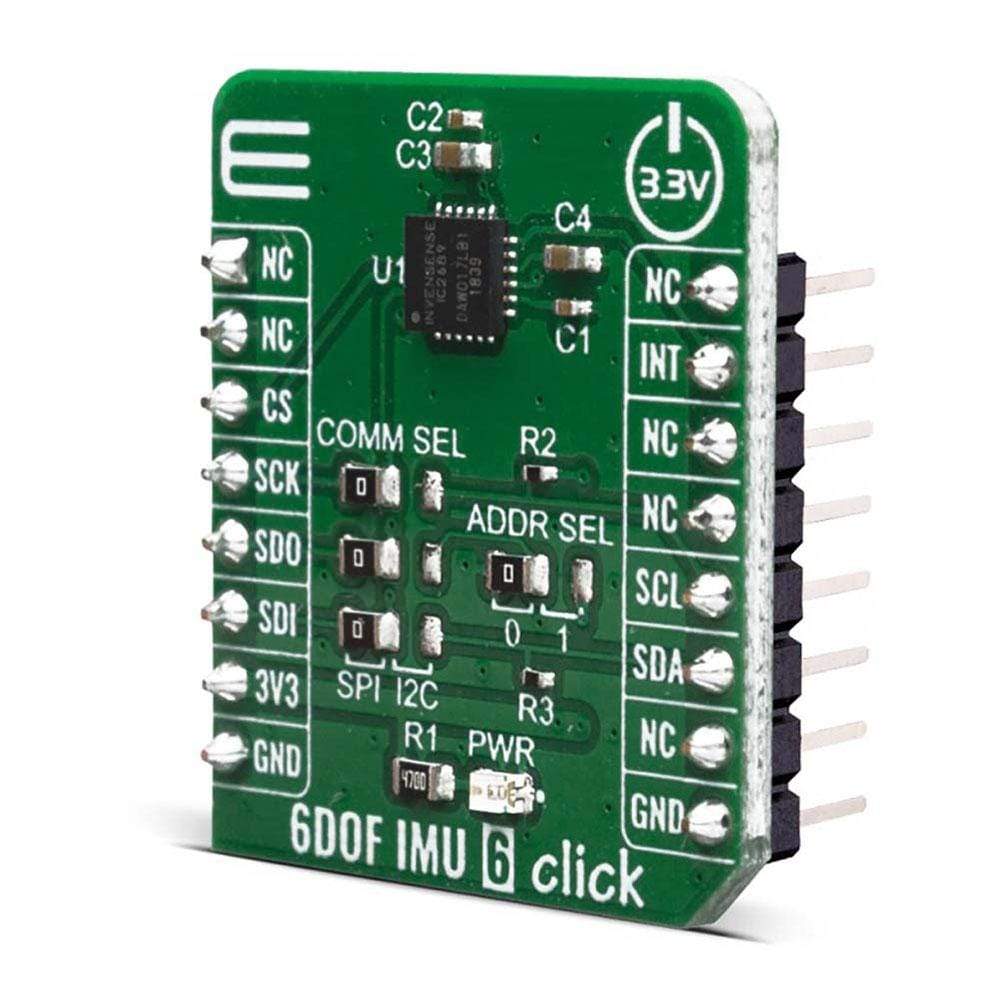

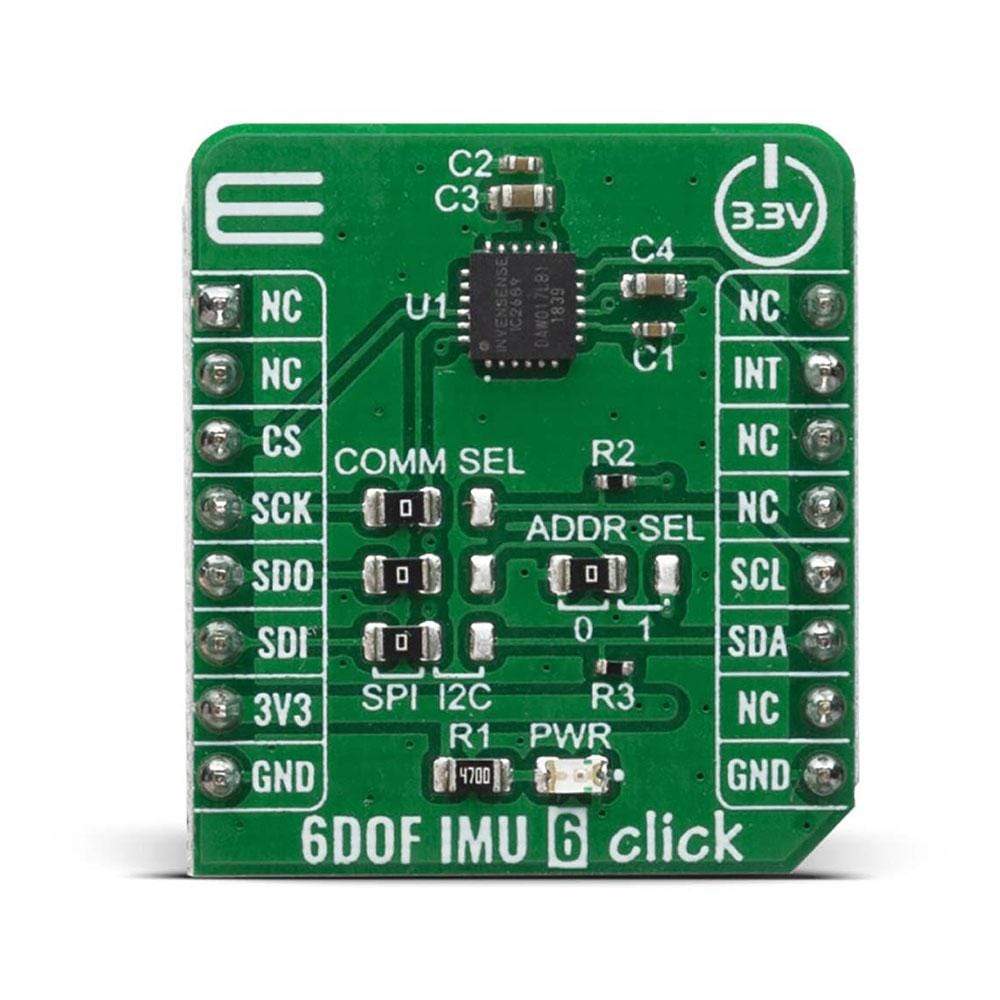

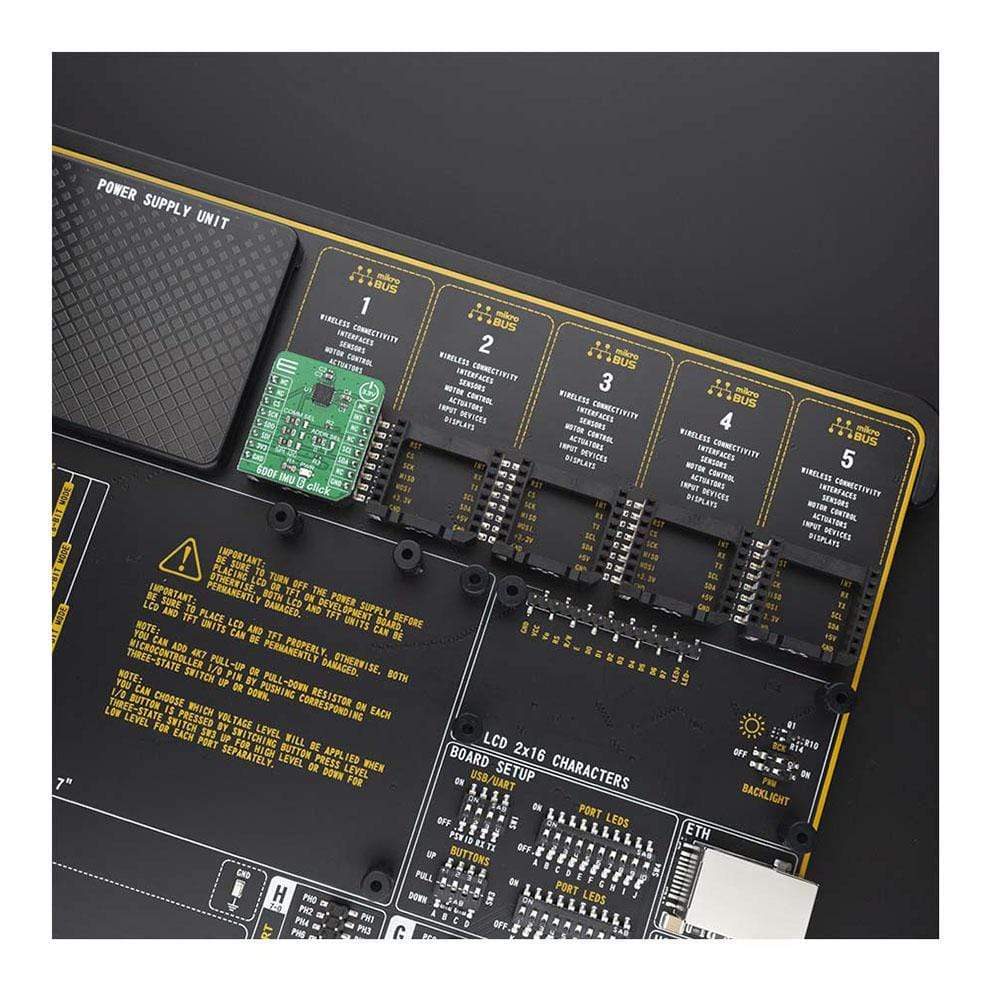

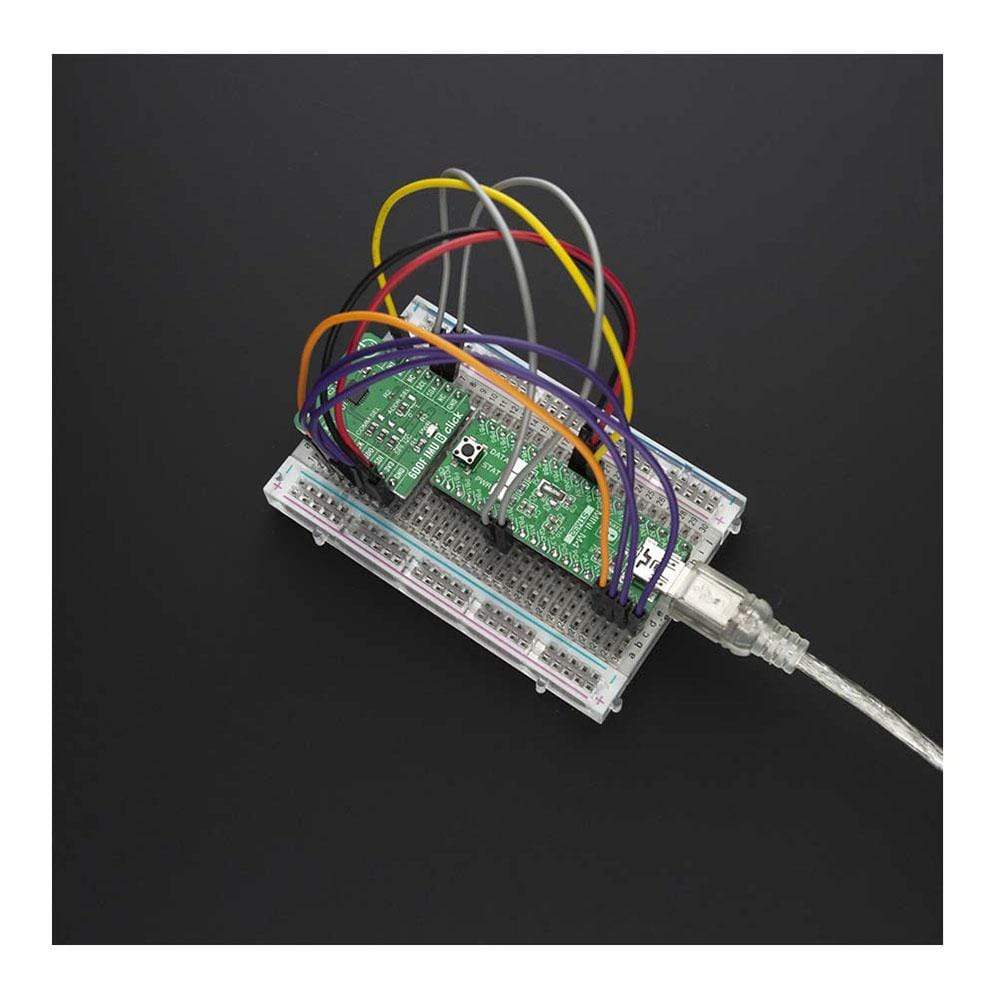

The 6DOF IMU 6 Click Board™ features a 6-axis motion tracking device that combines a 3-axis gyroscope, a 3-axis accelerometer, and a Digital Motion Processor™ (DMP) labelled as ICM-20689. The ICM-20689 from company TDK InvenSense includes on-chip 16-bit ADCs, programmable digital filters, an embedded temperature sensor, and programmable interrupts.

The gyroscope and accelerometer are full-scale range, user-programmable sensors with factory-calibrated initial sensitivity for reduced production-line calibration requirements.

Downloads

Das 6DOF IMU 6 Click Board™ verfügt über ein 6-Achsen-Bewegungsverfolgungsgerät, das ein 3-Achsen-Gyroskop, einen 3-Achsen-Beschleunigungsmesser und einen Digital Motion Processor™ (DMP) mit der Bezeichnung ICM-20689 kombiniert. Der ICM-20689 von TDK InvenSense enthält integrierte 16-Bit-ADCs, programmierbare digitale Filter, einen eingebetteten Temperatursensor und programmierbare Interrupts.

Das Gyroskop und der Beschleunigungsmesser sind benutzerprogrammierbare Sensoren mit vollem Messbereich und werkseitig kalibrierter Anfangsempfindlichkeit, um den Kalibrierungsbedarf in der Produktionslinie zu verringern.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4044

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.016 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018717088

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.