Overview

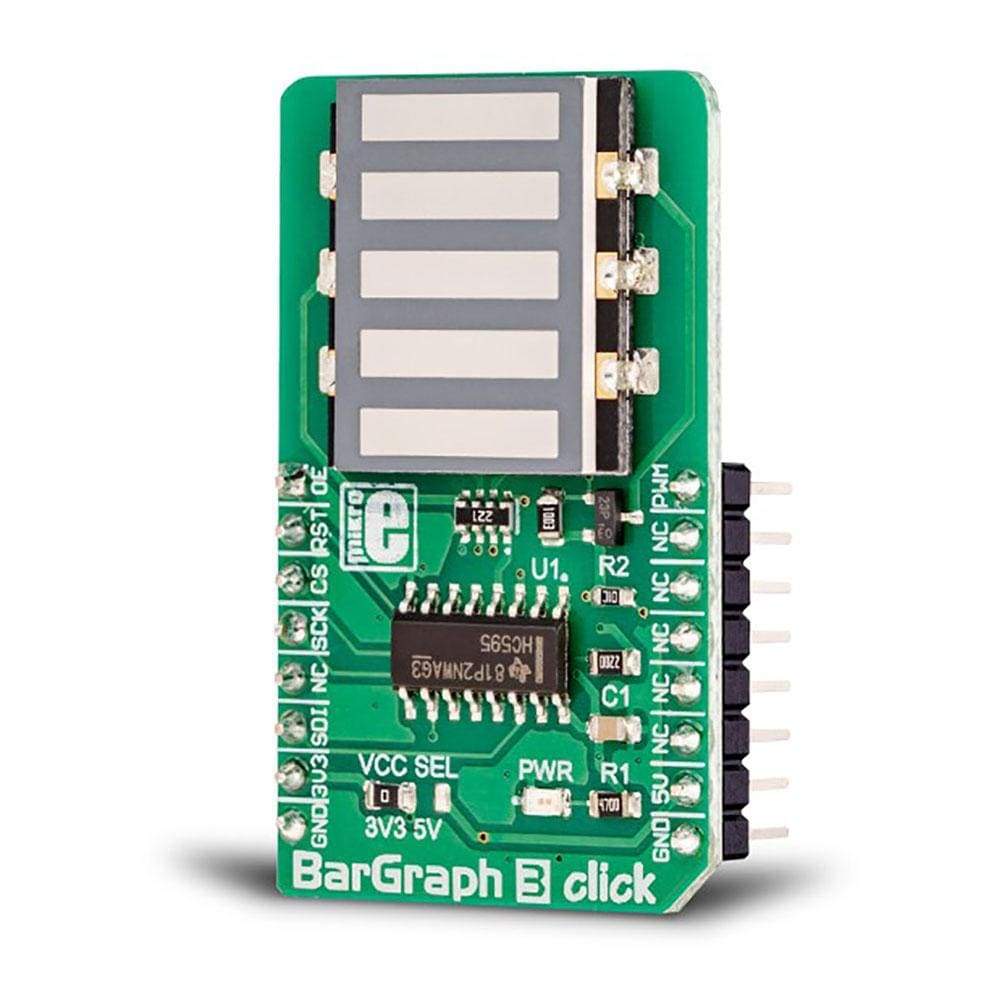

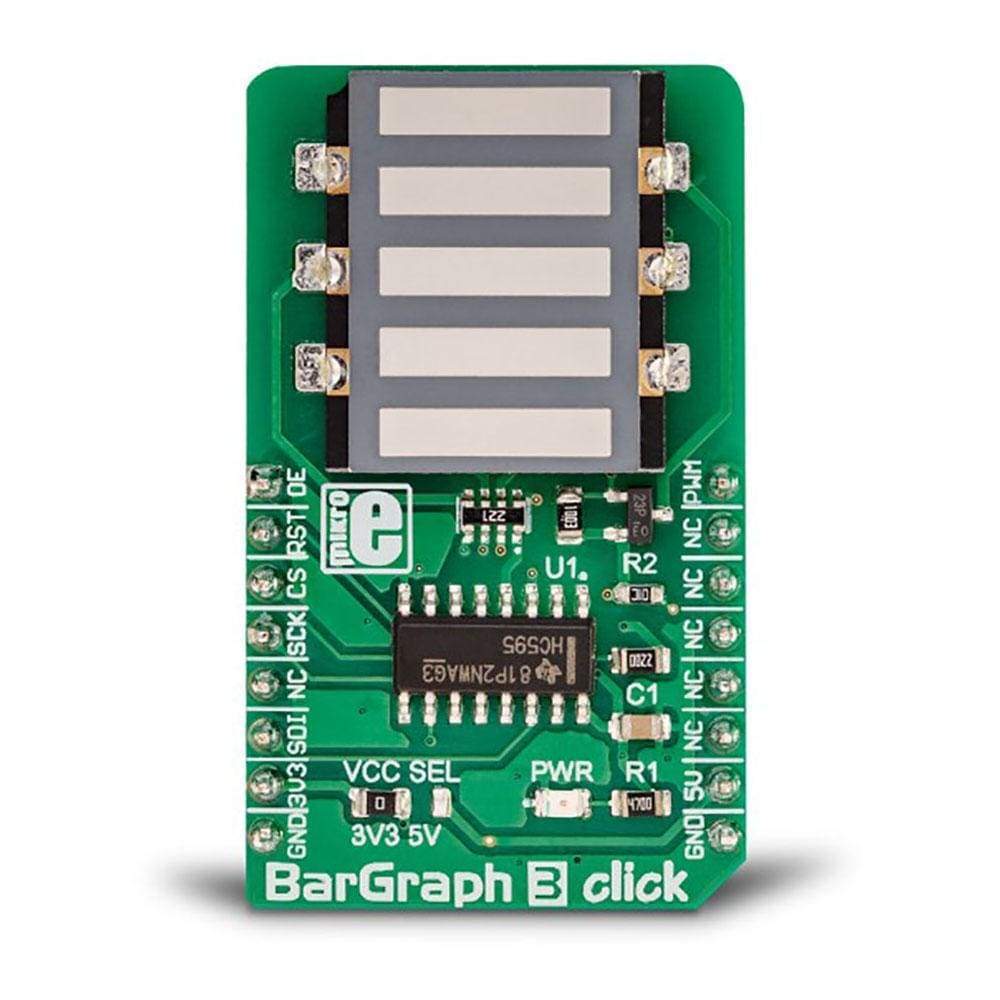

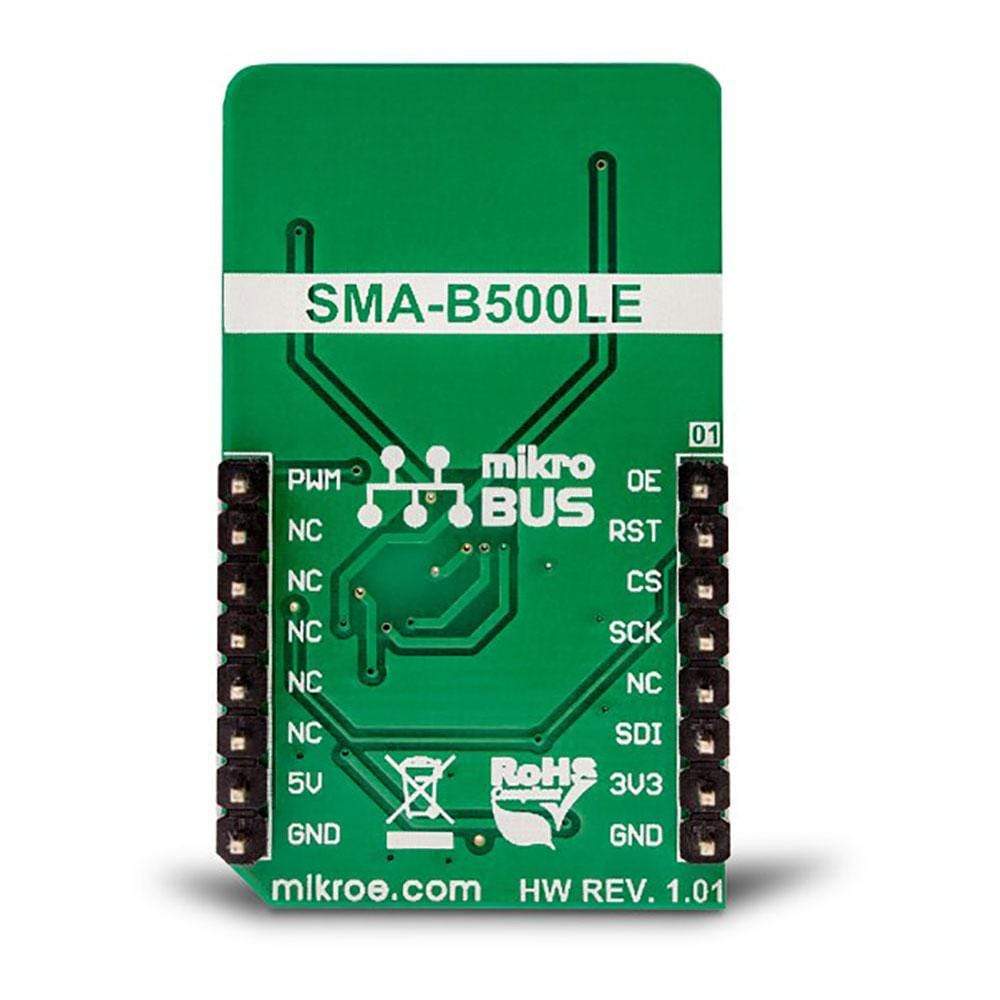

The BarGraph 3 Click Board™ is equipped with a five-segment LED bar graph display, notable for its strong and uniform illumination of the segments. Each segment consists of three internal LEDs with a common cathode, while the anodes of all LEDs are connected in a single point. This reduces the number of display bar pins to just six. The common anode is connected to the PWM pin of the mikroBUS via the P-type MOSFET, which can use the PWM signal from the microcontroller to change the intensity of the display. The fact that there are as many as three LEDs per segment makes the segments evenly illuminated, and the red colour of the light on the dark background makes segments visible.

It comes in a package with the mikroSDK software and a library with all the functions. The BarGraph 3 Click Board™ comes as a thoroughly tested and approved prototype, making it a reliable device ready to use on the development board.

Downloads

Das BarGraph 3 Click Board™ ist mit einem fünfsegmentigen LED-Balkendiagramm ausgestattet, das sich durch eine starke und gleichmäßige Beleuchtung der Segmente auszeichnet. Jedes Segment besteht aus drei internen LEDs mit einer gemeinsamen Kathode, während die Anoden aller LEDs an einem einzigen Punkt verbunden sind. Dadurch wird die Anzahl der Anzeigeleistenstifte auf nur sechs reduziert. Die gemeinsame Anode ist über den P-Typ-MOSFET mit dem PWM-Stift des MikroBUS verbunden, der das PWM-Signal vom Mikrocontroller verwenden kann, um die Intensität der Anzeige zu ändern. Die Tatsache, dass bis zu drei LEDs pro Segment vorhanden sind, sorgt für eine gleichmäßige Beleuchtung der Segmente, und die rote Farbe des Lichts auf dem dunklen Hintergrund macht Segmente sichtbar.

Es wird in einem Paket mit der MikroSDK-Software und einer Bibliothek mit allen Funktionen geliefert. Das BarGraph 3 Click Board™ wird als gründlich getesteter und zugelassener Prototyp geliefert und ist somit ein zuverlässiges Gerät, das sofort auf der Entwicklungsplatine verwendet werden kann.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3264

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.031 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018713967

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.