Overview

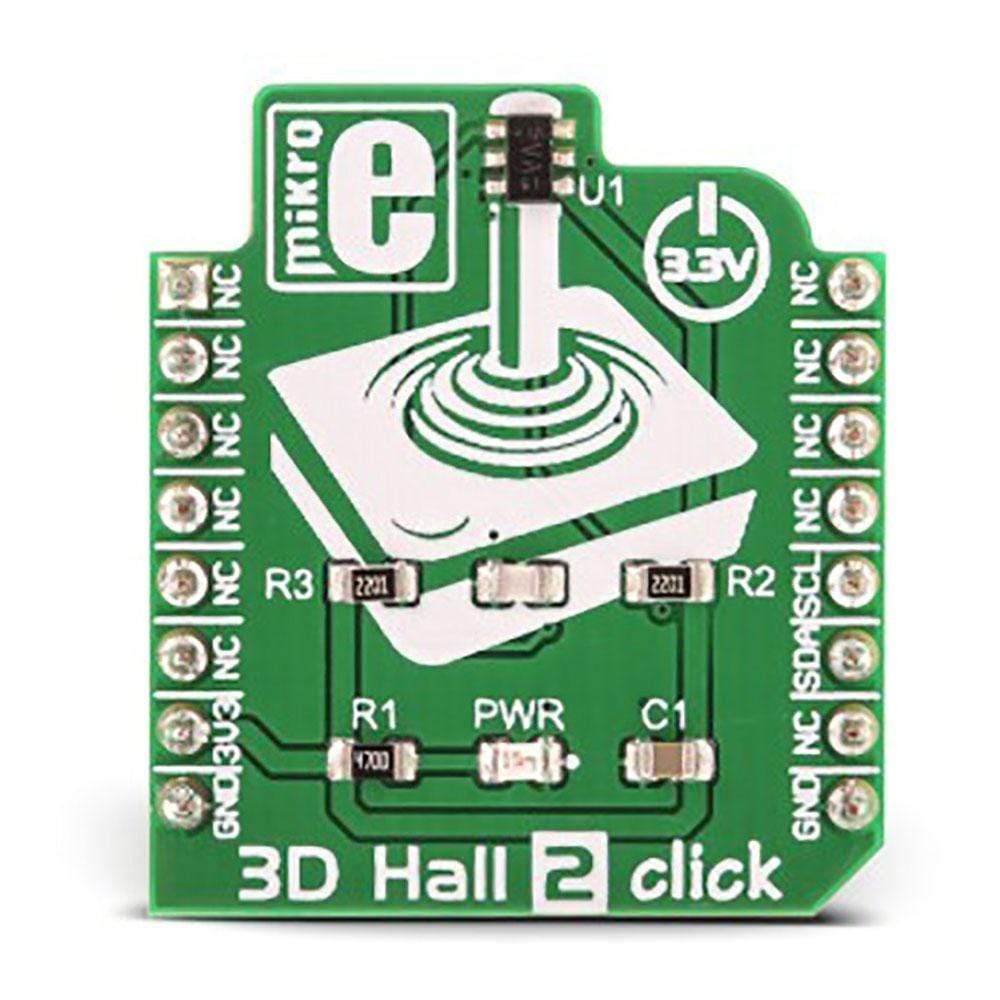

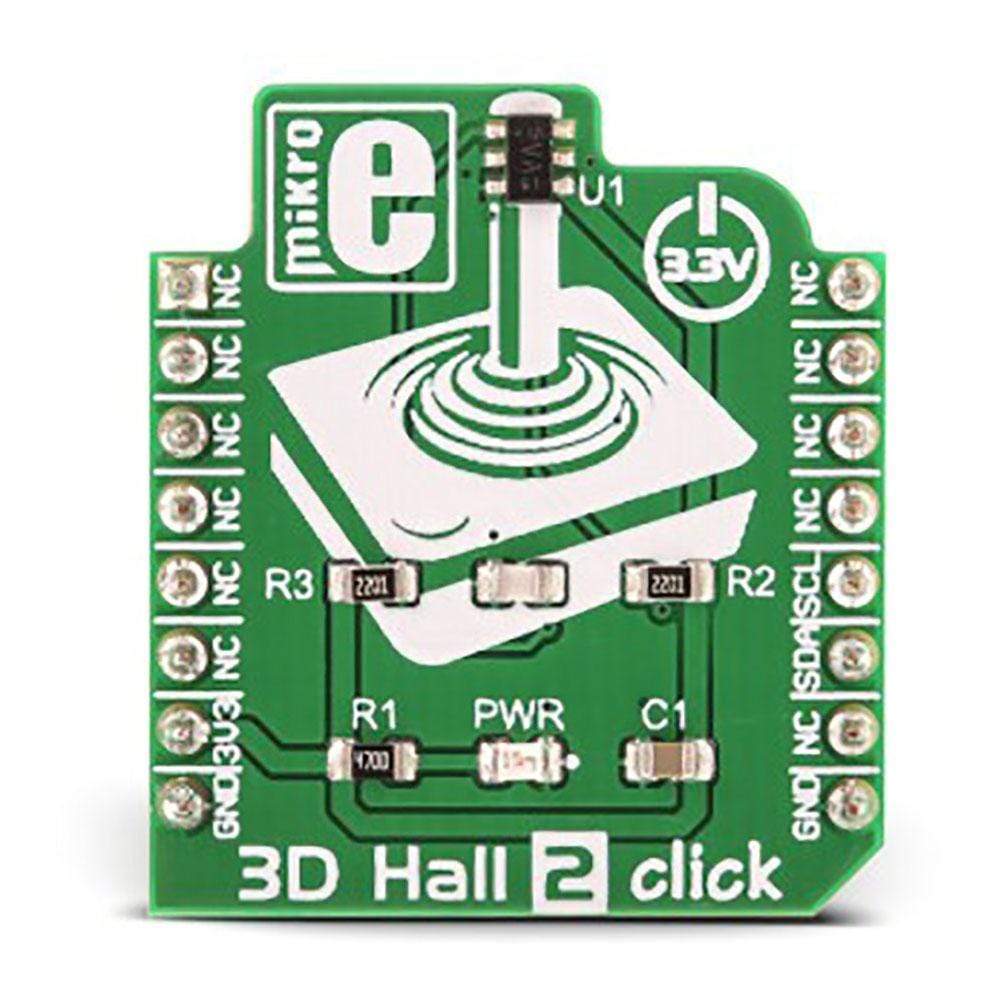

The 3D Hall 2 Click Board™ is a very accurate magnetic field sensing Click Board™, used to sense the magnetic field strength in three perpendicular axes. It relies on a TLV493D-A1B6, a low power 3D magnetic sensor from Infineon. This sensor has a separate Hall sensor for each axis, which allows a very reliable magnetic field sensing in 3D space, offering the basis for accurate angle calculations.

The TLV493D-A1B6 sensor uses an industry-standard I2C communication interface and requires a very low count of external components. The I2C interface is also used for the chip reset, so the sensor features a very low count of pins.

Downloads

Das 3D Hall 2 Click Board™ ist ein sehr genaues Click Board™ zur Magnetfelderfassung, das zur Erfassung der Magnetfeldstärke in drei senkrechten Achsen verwendet wird. Es basiert auf einem TLV493D-A1B6, einem stromsparenden 3D-Magnetsensor von Infineon. Dieser Sensor verfügt über einen separaten Hall-Sensor für jede Achse, was eine sehr zuverlässige Magnetfelderfassung im 3D-Raum ermöglicht und die Grundlage für genaue Winkelberechnungen bietet.

Der TLV493D-A1B6-Sensor verwendet eine I2C-Kommunikationsschnittstelle nach Industriestandard und erfordert nur sehr wenige externe Komponenten. Die I2C-Schnittstelle wird auch für den Chip-Reset verwendet, sodass der Sensor nur sehr wenige Pins hat.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3190

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.017 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018713653

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.