Overview

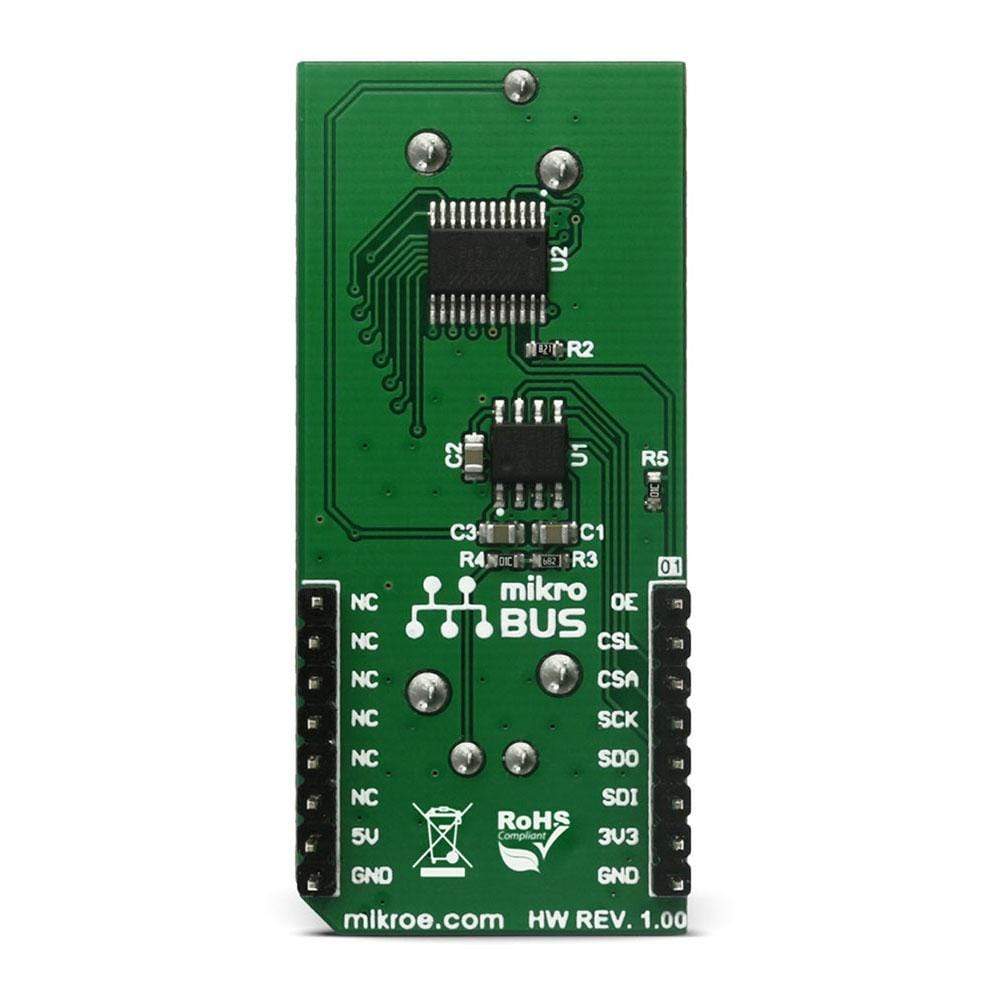

The Slider Click Board™ features a mechanical slide action potentiometer - a slider, which gives a nice feeling when actuating, along with 16 SMD LEDs, that can be used for any kind of visual feedback. The on-board high-resolution 22-bit ADC can detect even the smallest move, faithfully capturing the smoothness of the slider movement, while digitizing its position. The 16 on-board SMD LEDs can give a nice visual feedback of the slider position, but those LEDs can also be used for other purposes since they are not hardwired to the slider.

The Slider Click Board™ can be used to control various digital applications with an accurate and comfortable slider potentiometer, while the LEDs can be used to display the desired information in a form of a bar or a position. For example, Slider Click Board™ can be used to control a quad digital potentiometer, such as the one that can be found on DIGIPOT 5 Click Board™, while displaying the position of the selected digital wiper on the LEDs.

Downloads

Der Slider Click Board™ verfügt über ein mechanisches Schiebepotentiometer – einen Schieber, der beim Betätigen ein angenehmes Gefühl vermittelt, sowie 16 SMD-LEDs, die für jede Art von visuellem Feedback verwendet werden können. Der integrierte hochauflösende 22-Bit-ADC kann selbst die kleinste Bewegung erkennen, die Gleichmäßigkeit der Schieberbewegung originalgetreu erfassen und gleichzeitig seine Position digitalisieren. Die 16 integrierten SMD-LEDs können ein schönes visuelles Feedback der Schieberposition geben, aber diese LEDs können auch für andere Zwecke verwendet werden, da sie nicht fest mit dem Schieber verdrahtet sind.

Mit dem Slider Click Board™ können Sie verschiedene digitale Anwendungen mit einem präzisen und komfortablen Schiebepotentiometer steuern, während die LEDs die gewünschten Informationen in Form eines Balkens oder einer Position anzeigen. Beispielsweise kann das Slider Click Board™ verwendet werden, um ein digitales Quad-Potentiometer zu steuern, wie es auf dem DIGIPOT 5 Click Board™ zu finden ist, während die Position des ausgewählten digitalen Wischers auf den LEDs angezeigt wird.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2702

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.025 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018711741

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.