Overview

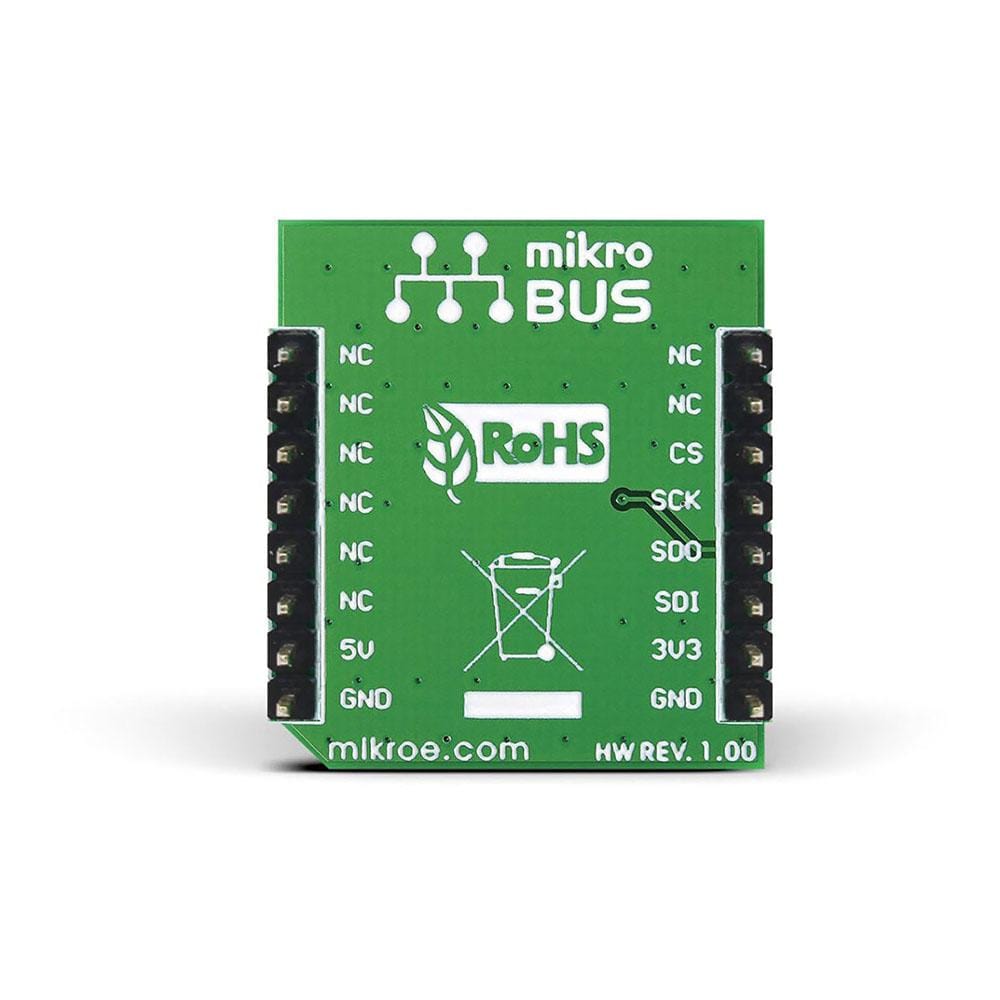

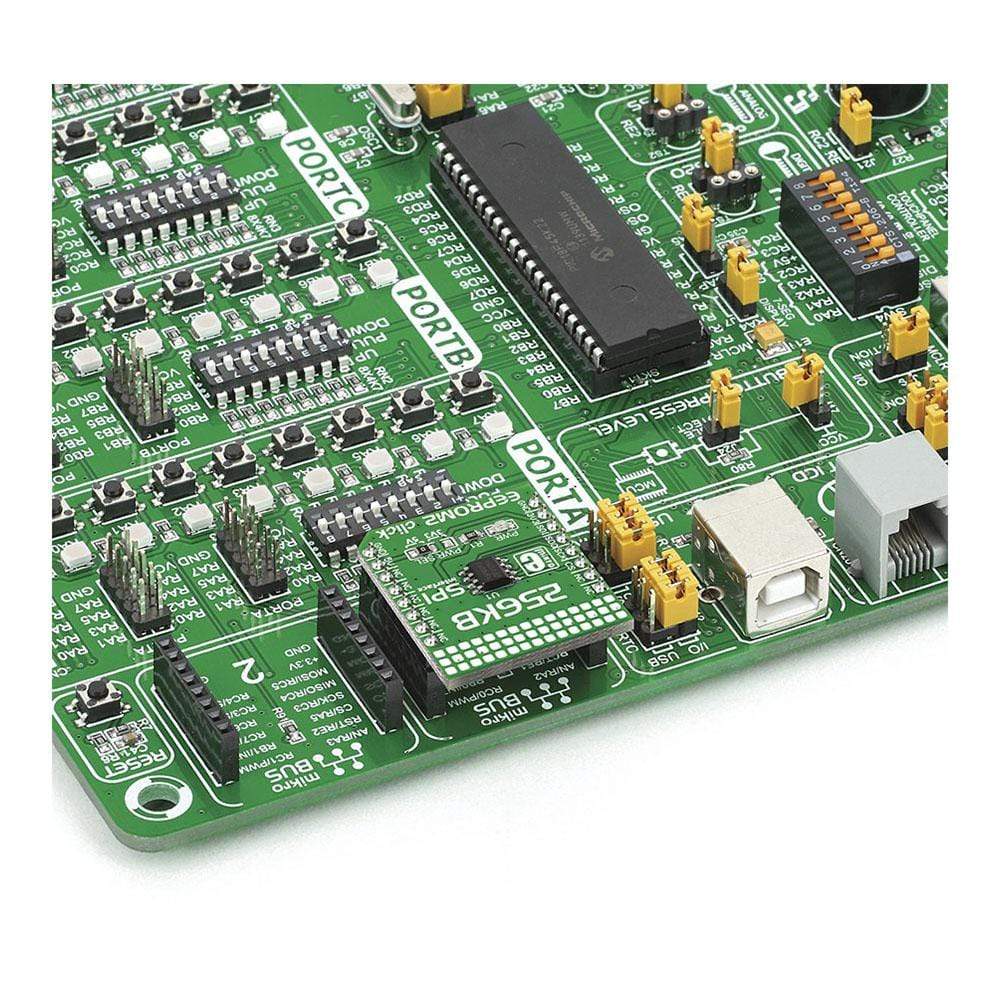

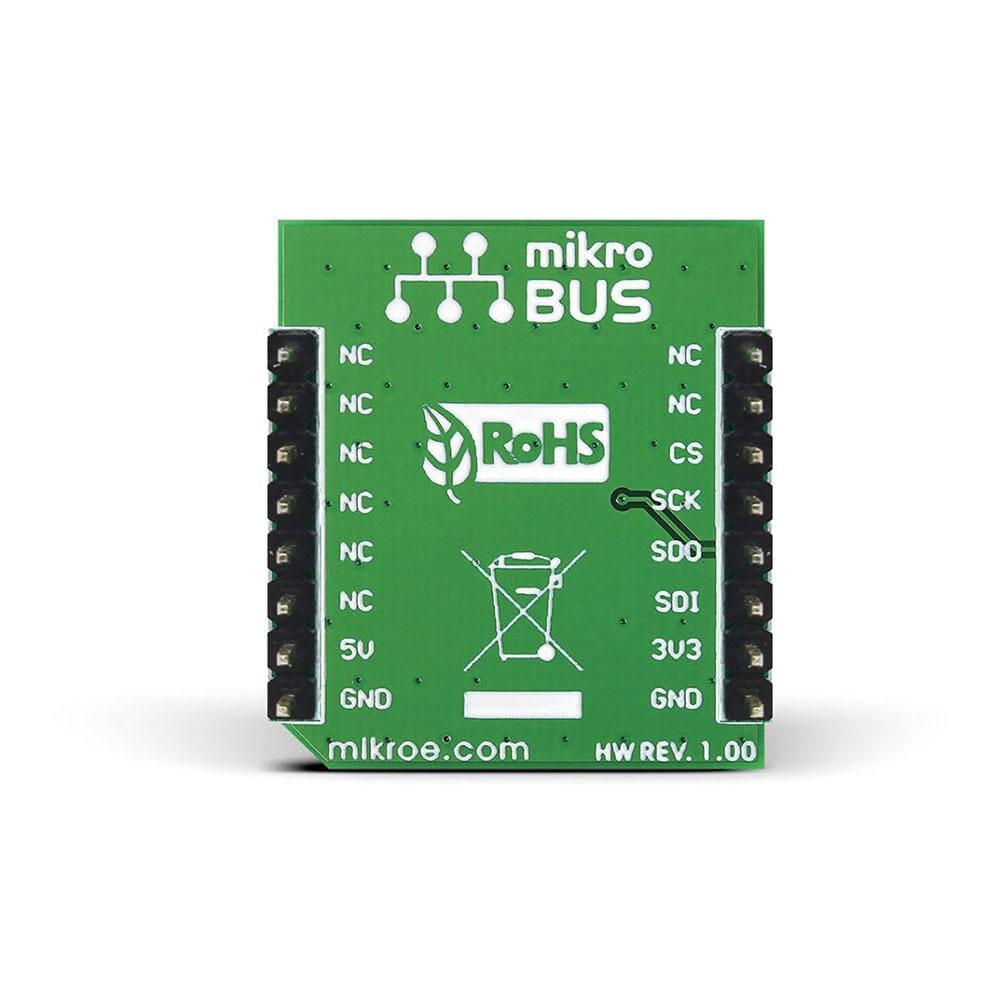

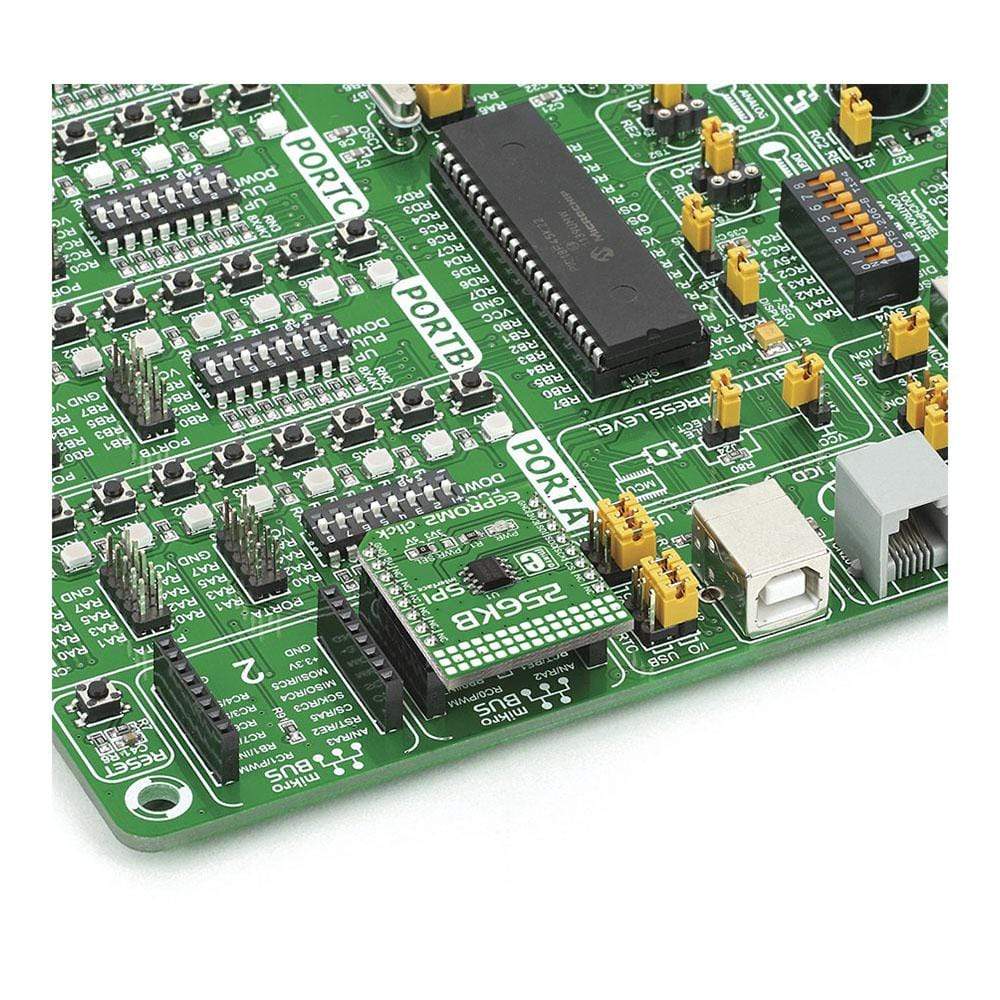

The EEPROM 2 Click Board™ carries ST's M95M02-DR DIP-8 socket EEPROM chip with 256 KB of memory. The chip has byte and page write speeds equal to or less than 10 ms.

Downloads

Das EEPROM 2 Click Board™ enthält den M95M02-DR DIP-8-Sockel-EEPROM-Chip von ST mit 256 KB Speicher. Der Chip hat Byte- und Seitenschreibgeschwindigkeiten von höchstens 10 ms.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-1909

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.024 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606015076621

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.