Overview

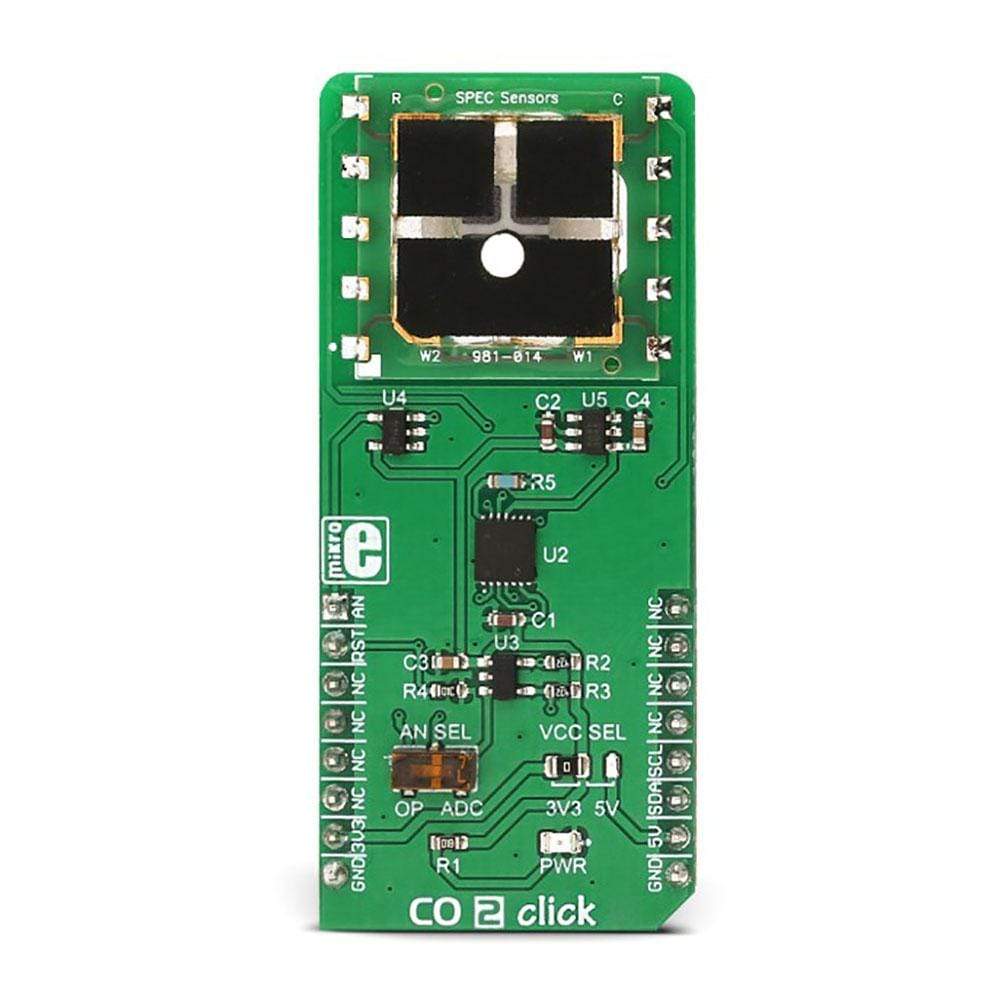

The CO 2 Click Board™ is a very accurate, carbon-monoxide-gas-sensor Click Board™, equipped with the SPEC amperometric, 3SP CO 1000 gas sensor which electrochemically reacts with the carbon monoxide (CO). It is supported by the LMP91000, a high-precision integrated analogue front-end IC (AFE), perfectly suited for use in electrochemical, sensing applications.

The CO 2 Click Board™ also provides the reference voltage required by the sensor and it offers a choice between the analogue output from the AFE IC buffered with the low noise op-amp, and the digital output from the 12-bit SAR A/D converter.

Downloads

Das CO 2 Click Board™ ist ein sehr genaues Click Board™ mit Kohlenmonoxid-Gassensor, ausgestattet mit dem amperometrischen 3SP CO 1000-Gassensor SPEC, der elektrochemisch mit Kohlenmonoxid (CO) reagiert. Es wird vom LMP91000 unterstützt, einem hochpräzisen integrierten analogen Front-End-IC (AFE), der sich perfekt für den Einsatz in elektrochemischen Sensoranwendungen eignet.

Das CO 2 Click Board™ stellt außerdem die vom Sensor benötigte Referenzspannung bereit und bietet die Wahl zwischen dem analogen Ausgang vom mit dem rauscharmen Operationsverstärker gepufferten AFE IC und dem digitalen Ausgang vom 12-Bit-SAR-A/D-Wandler.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3196

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.021 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018713639

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.