Overview

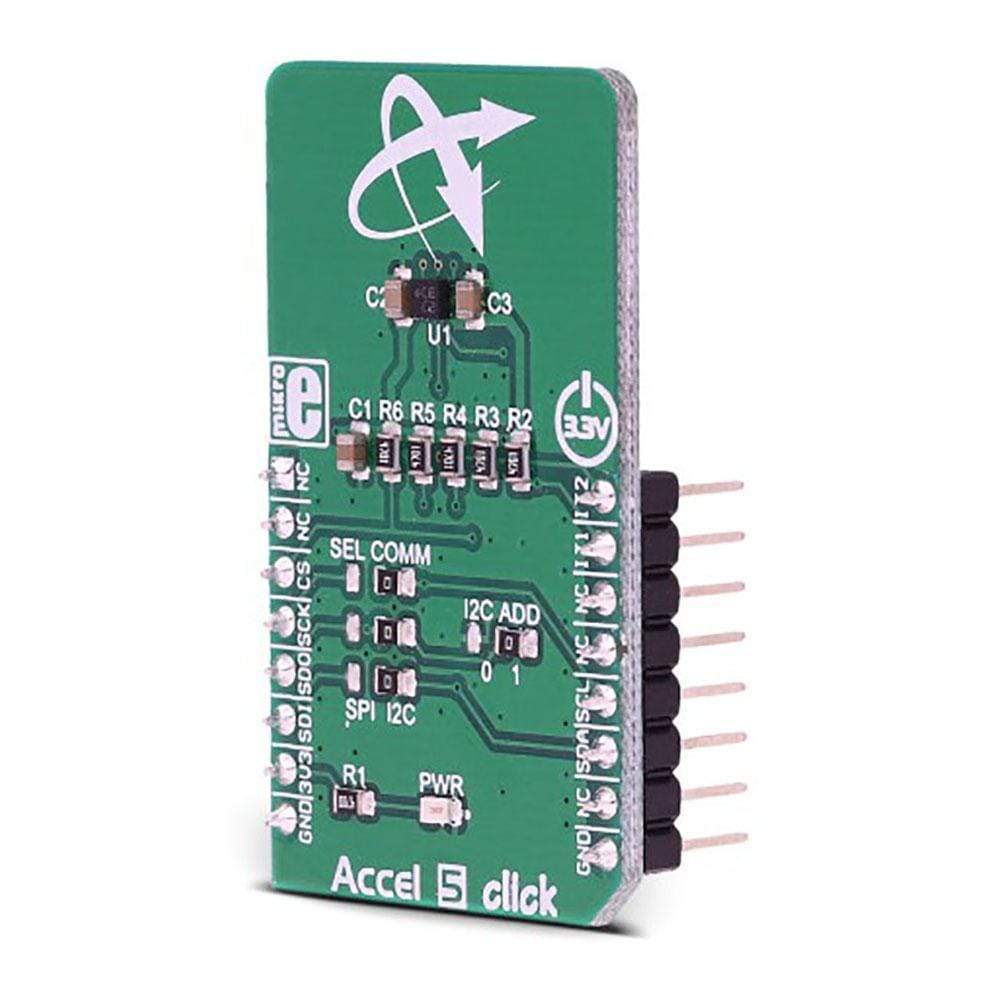

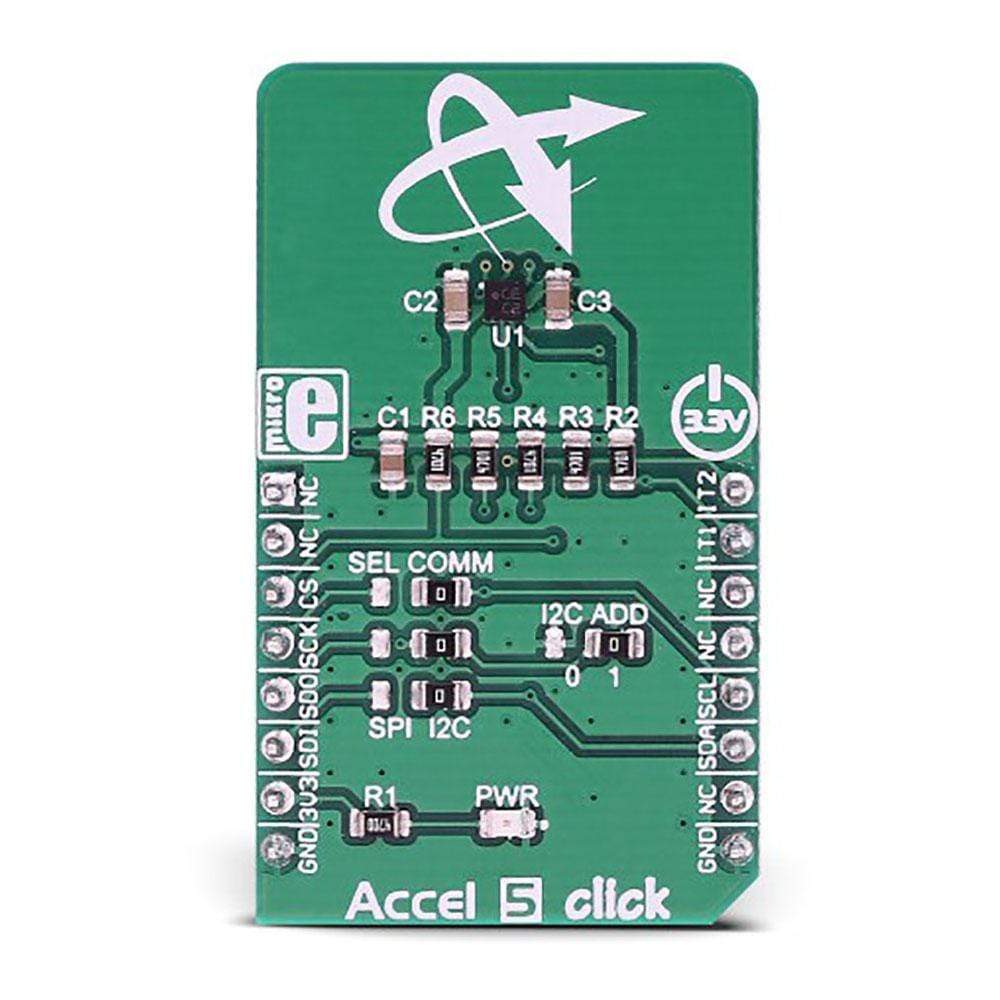

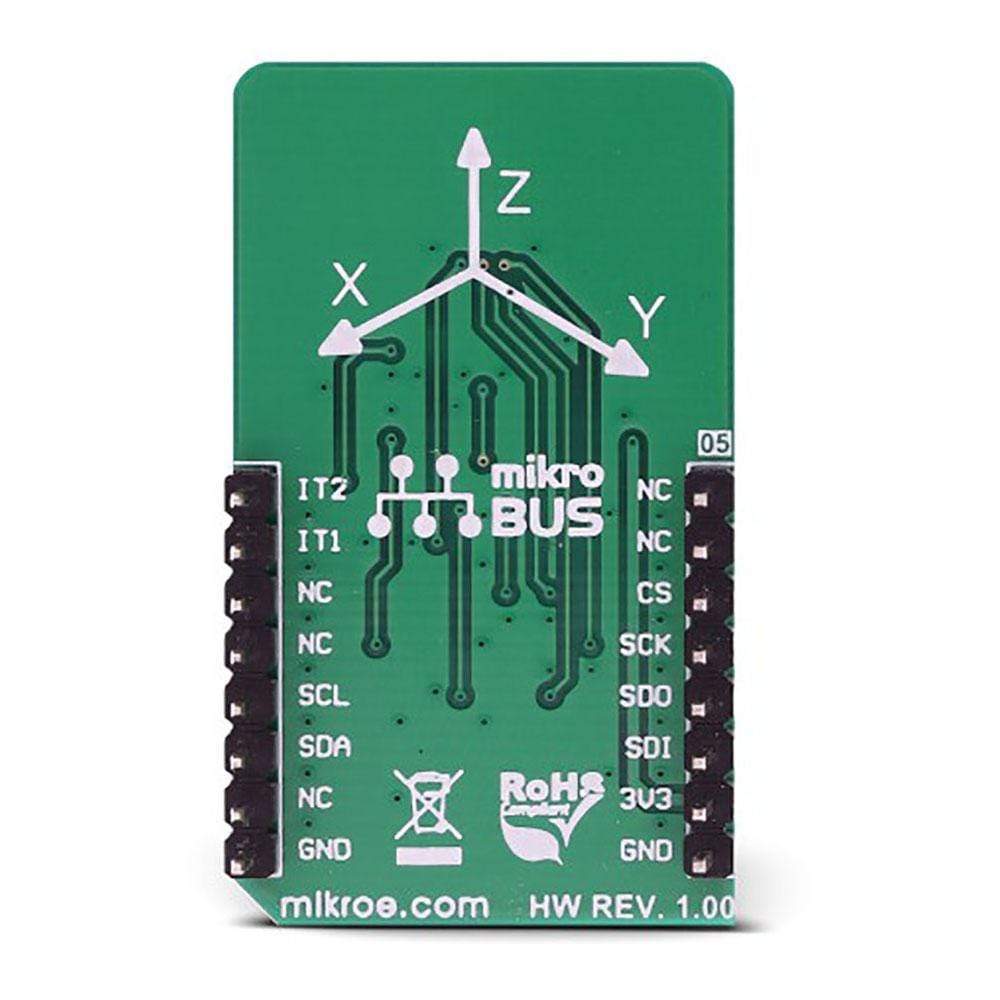

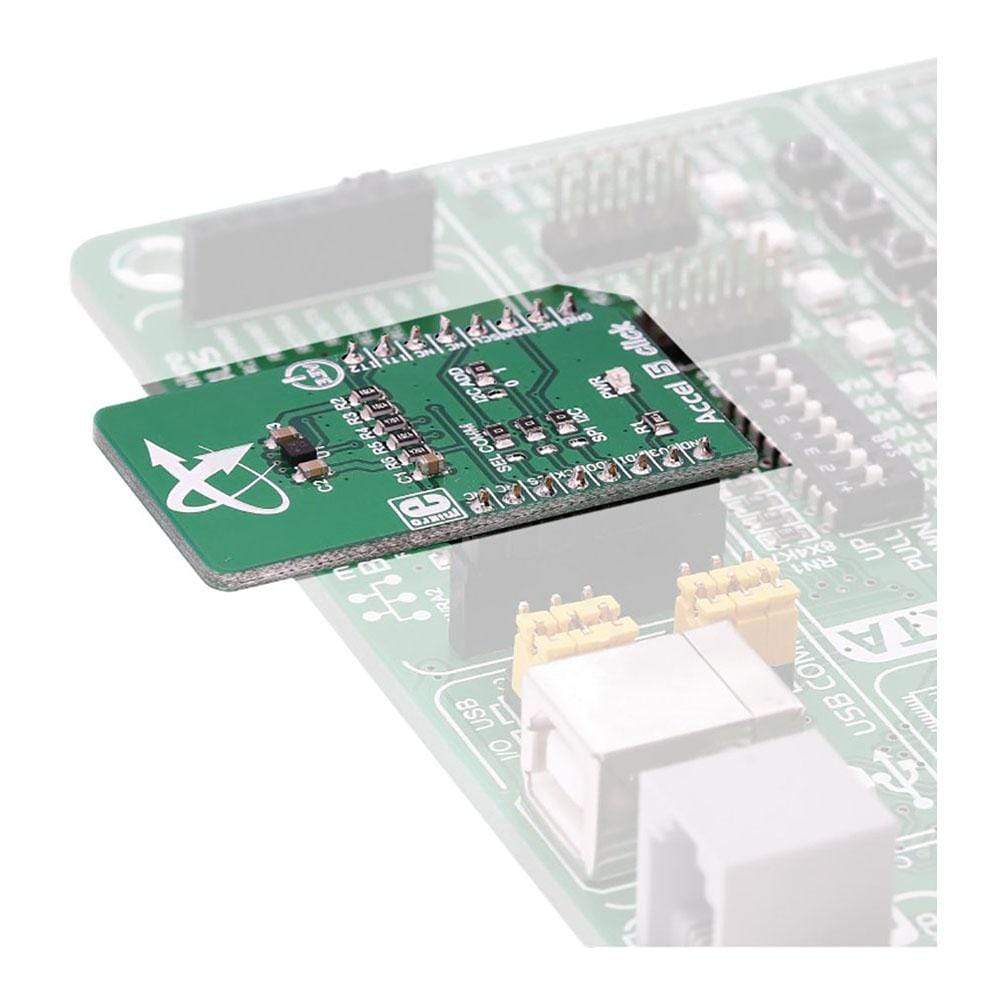

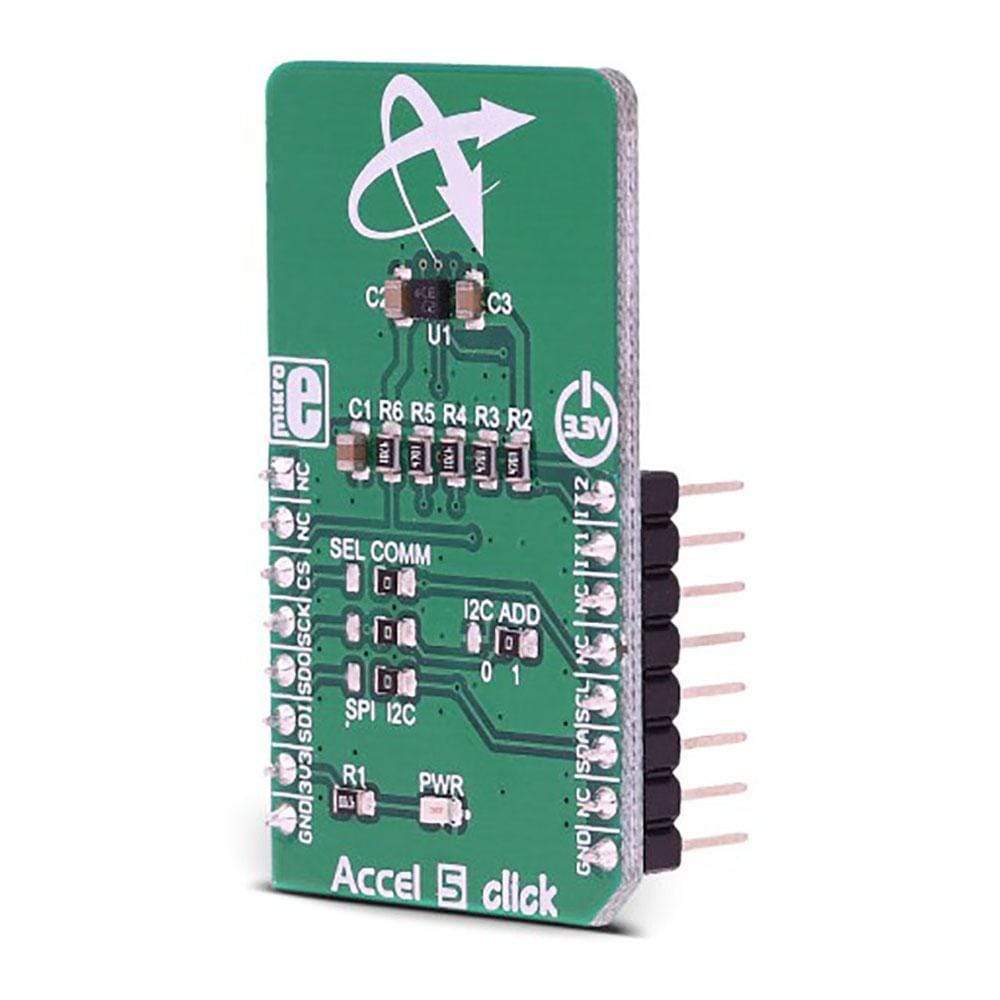

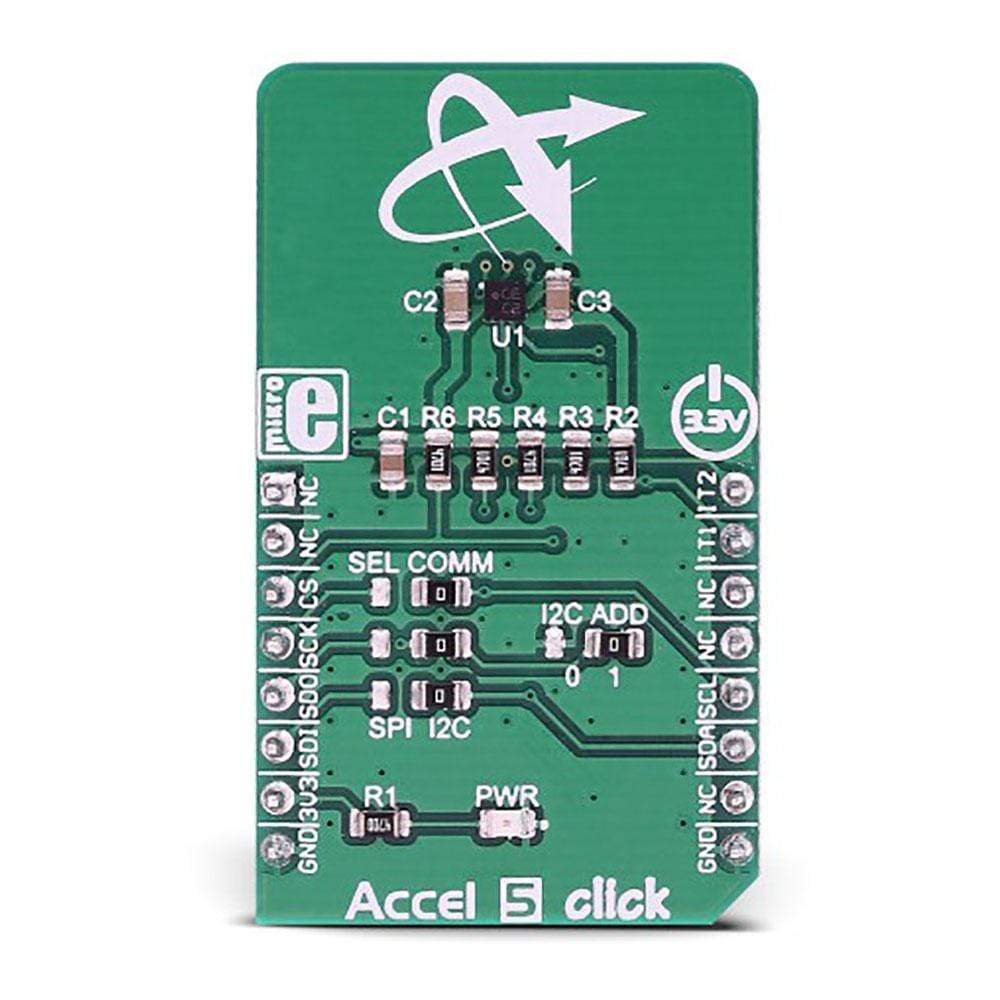

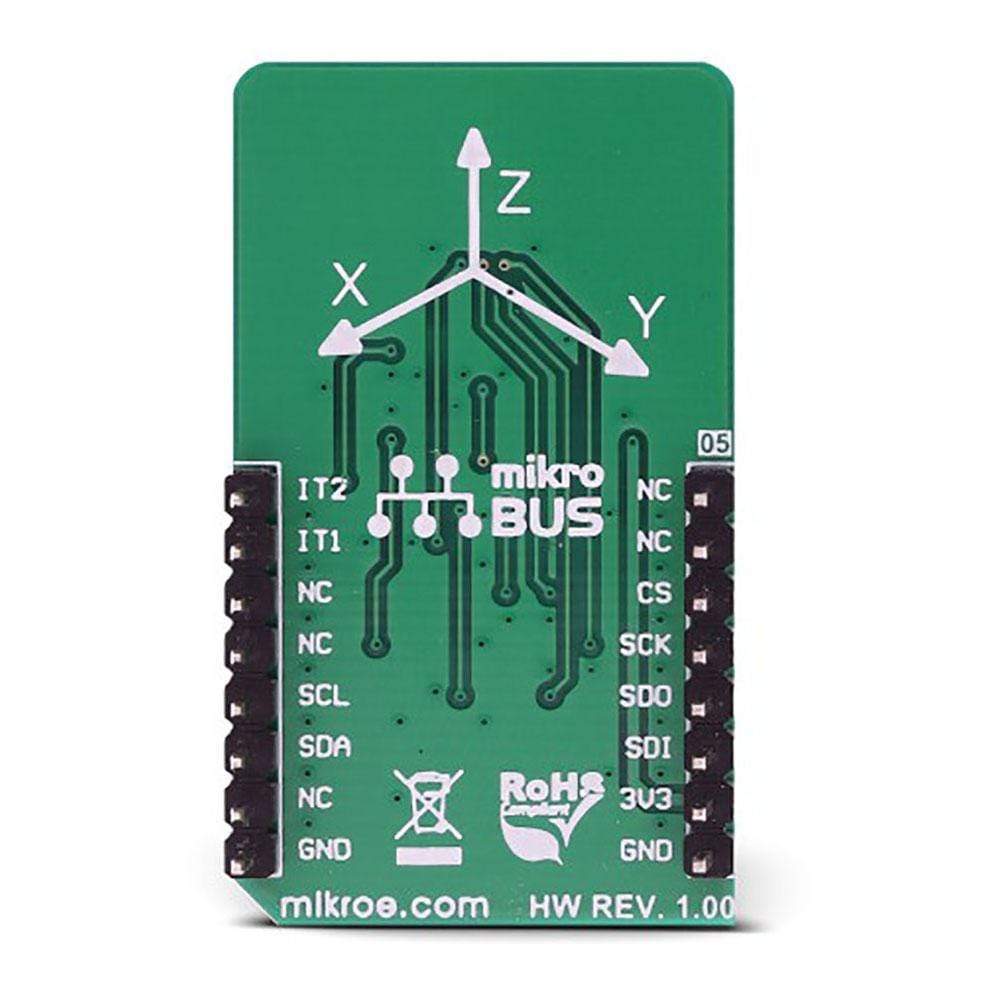

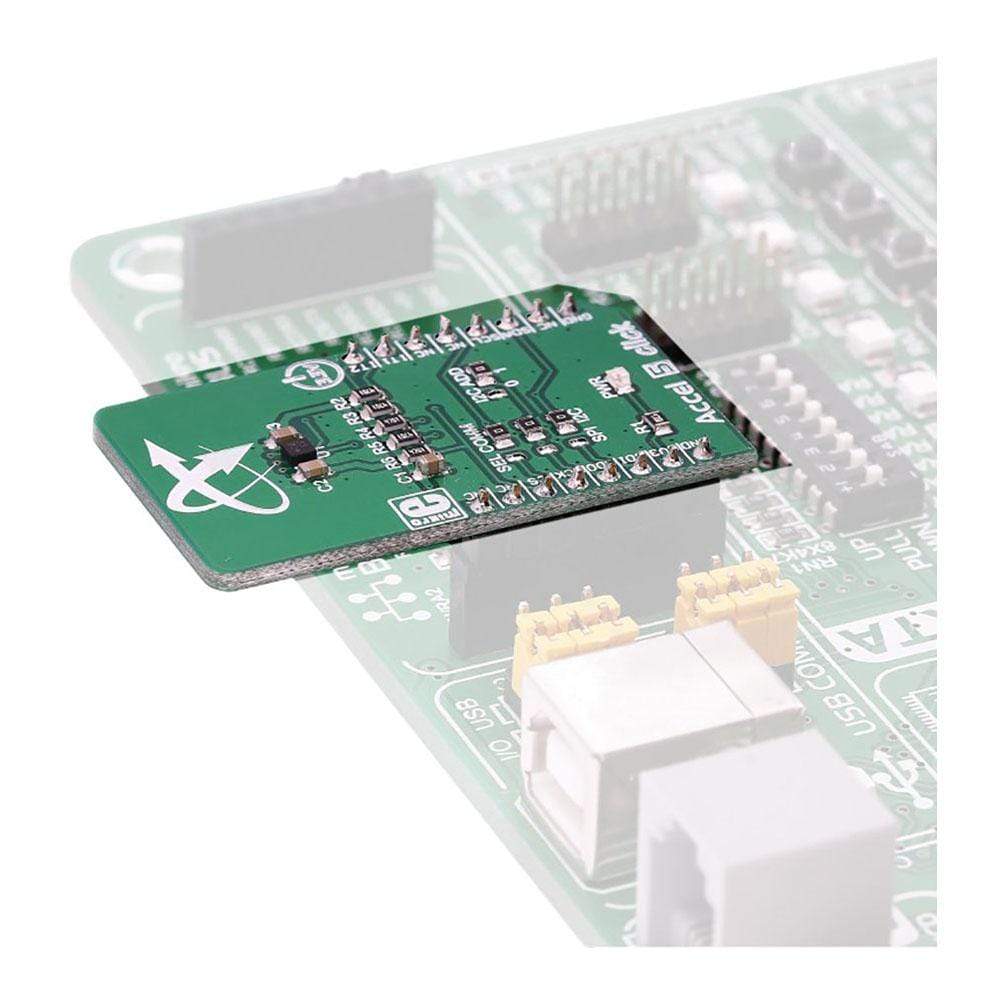

The Accel 5 Click Board™ features an ultra-low power triaxial accelerometer sensor, labelled as the BMA400. This Click Board™ allows linear motion and gravitational force measurements in ranges of ±2g, ±4g, ±8g, and ±16g in three perpendicular axes. Besides the acceleration measurement, the Accel 5 Click Board™ is able to output an interrupt for many different events, including tap, double-tap, step counting, activity recognition (walk, run, stand still), activity change (any type of acceleration pattern change), orientation, and more.

It features onboard data processing, offering the acceleration data directly, over the standard I2C or SPI interface. However, a key feature of the BMA400 sensor is its extremely low power consumption.

Downloads

Der Accel 5 Click Board™ verfügt über einen dreiachsigen Beschleunigungssensor mit extrem niedrigem Stromverbrauch, der als BMA400 bezeichnet wird. Dieses Click Board™ ermöglicht lineare Bewegungs- und Gravitationskraftmessungen in Bereichen von ±2 g, ±4 g, ±8 g und ±16 g in drei senkrechten Achsen. Neben der Beschleunigungsmessung kann das Accel 5 Click Board™ einen Interrupt für viele verschiedene Ereignisse ausgeben, darunter Tippen, Doppeltippen, Schrittzählung, Aktivitätserkennung (Gehen, Laufen, Stillstehen), Aktivitätsänderung (jede Art von Änderung des Beschleunigungsmusters), Ausrichtung und mehr.

Es verfügt über eine integrierte Datenverarbeitung und bietet die Beschleunigungsdaten direkt über die Standardschnittstelle I2C oder SPI. Ein wichtiges Merkmal des BMA400-Sensors ist jedoch sein extrem niedriger Stromverbrauch.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3149

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.019 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018713523

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.